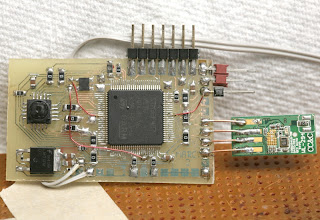

STM32 bugs continued to torment. This time, the transmit operation ended up requiring multiple 64 byte packets. The demo showed multiple packets of 512 bytes. The receive operation allows any size buffer.

Also not in the demo, between transmit operations, you need a polling loop which waits for the urb status to not equal IDLE. Not equalling IDLE actually means it is idle. No receive or transmit operation can occur until the urb is not IDLE. Of course, the urb status is always IDLE before the 1st send request.

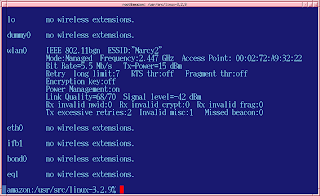

Networking got to the minimum level for a camera test. It does 0-800kbit/sec with lots of packet loss. This is using the ground station to send beacons & the aircraft to send 1024 bytes per beacon, all UDP, just like the final product. It would be much more complicated to have the aircraft send continuously. There isn't enough memory or latency tolerance to use TCP.

The 802.11 auth, assoc, & UDP packet generation are just good enough to work, even with the USB packet loss. The ARP table & DHCP is still manual. The hope is moving ahead will show more aspects of the latest USB problem.

Power consumption is a real problem. The DPAK LM317 starts smoking during 800kbit transmission, with no camera. A simple camera board obviously requires a lot of power hardware.

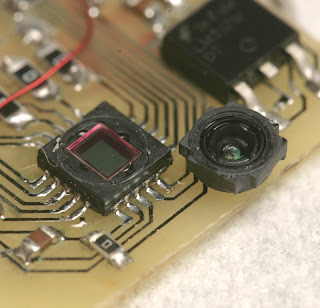

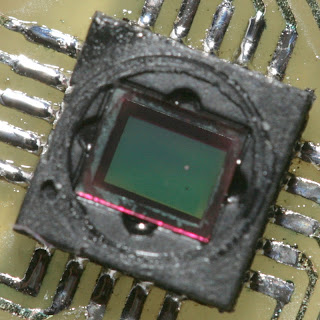

The board & camera were finally mated. Because Vdd appears in the same place on 3 of the corners, pin 1 ended up soldered wrong, which resulted in a hot air heating.

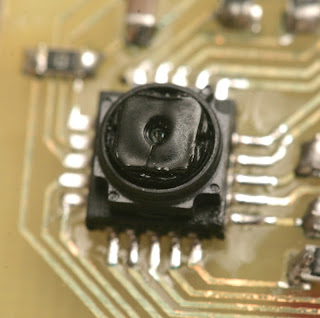

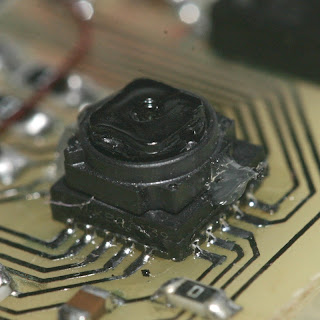

That melted it. Eventually heat it from behind & got it to fall off. The focus ring is now welded into place. The 1st pictures will be blurry, but hopefully good enough to characterize the rolling shutter.

This was the only part that only got 1 order, due to lack of money. This shows how the actual cost is much higher than the BOM.

Like any lens, it's not attached by much, & trying to turn a melted focus ring only rips off the lens.

Definitely some evidence of the focus ring melting all the way through.

The problem with these cameras is not the sensor as much as getting a sensor & lens combination in that size. Sensors are abundant. Could even use a CCD sensor & be done with warping, if the lens materialized.

Comments

Nice. I had a lot of problem getting a lens + holder working for the optical flow. Of course you're going right down to doing the actual image processing on your CPU which I'm sure will be very tricky. good luck.