Apellix utilizes large lift capacity drones attached to a base station with an umbilical cord and tether system

Apellix utilizes large lift capacity drones attached to a base station with an umbilical cord and tether system

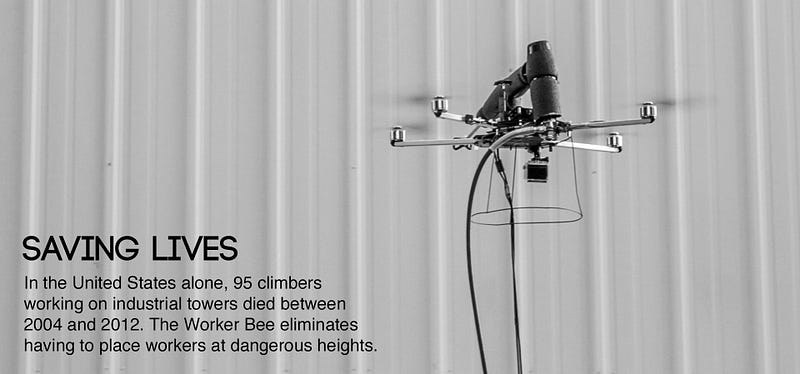

In the United States alone, 95 climbers working on industrial towers died between 2004 and 2012. Worker safety is a concern across industries but perhaps no more so than in large-scale workplaces like oil & gas, shipping, and infrastructure. Add in the financial expense of maintaining massive structures like ships, water towers, bridges, and skyscrapers — it’s an industry that has needed technological innovation for decades.

Enter the drone, those charming little creatures that take our picture at concerts, capture amazing fireworks displays at night, and deliver our packages. Couldn’t we utilize them to facilitate some real change? I think we can, so I founded a company to prove it.

Let’s look at an example of what it is currently like to paint a large cruise or cargo ship.

Fun facts:

- A mega cruise ship has an underwater hull area (the part you don’t see), keel-to-deep-load line of over 120,000 square feet. That’s about four times larger than a big box store like Wal-Mart. In other words — HUGE

- It takes over $100,000 worth of paint for a standard size cruise or cargo ship (60,000 to 80,000 square feet).

- It takes a work crew of about 30 people four days to set up scaffolding, paint, and remove the scaffolding.

- The time that ship spends in dry dock while it’s painted translates into lost revenue, an amount that can exceed $1,000,000 a day

Now imagine what it would mean if a single machine operator, with no work crew and no scaffolding, from the safety of the ground, could launch an industrial robotics system that completes the job in a single day. That is what we make possible at Apellix.

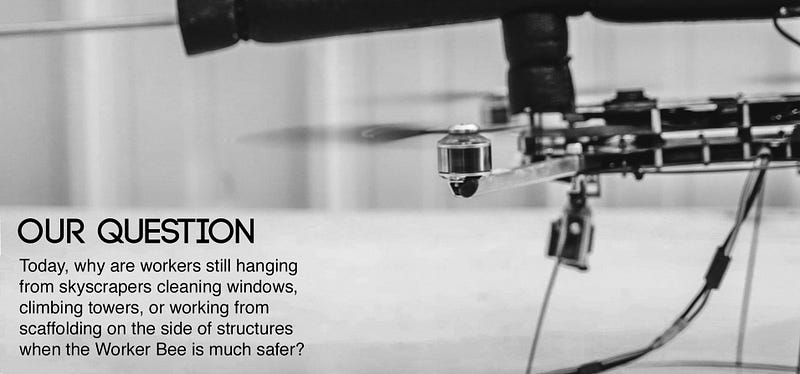

Our Worker Bee robotics system eliminates the need to place human workers at dangerous heights. Using large lift capacity drones attached to a base station with an umbilical cord and tether, and custom software that ties it all together, the robotics modular system can paint buildings and towers, wash windows, safely apply chemicals and much much more.

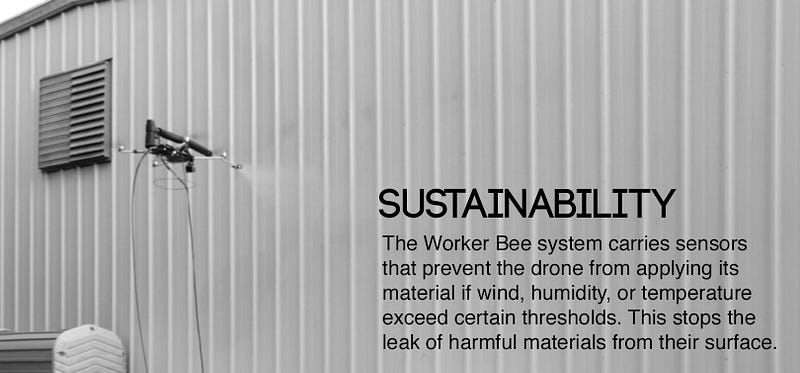

By replacing human judgement with science, you can increase safety and productivity, reduce costs, and provide measured standardized quality with environmentally sustainable benefits. Unlike most industrial technology, which solves operational problems or increases output efficiency or quality, the Apellix Drone + Robotics platform keeps workers safe so companies can focus on their operations.

We believe this is pretty unique. Apellix uses proprietary hardened, industrial customized software to enable its drone-based applicators to do things drones have never done before. The market potential is huge — $127B worth of paint is sold each year. And the possible applications are myriad, from painting to cleaning industrial equipment to rapidly deploying shelter to disaster areas to 3D-printing at tremendous scale.

Today marks the official launch of the Apellix Worker Bee concept. We’re currently in pre-production with a fourth-generation industrial robotics spray paint system and hope to enter into commercial testing with a partner in the coming quarter. If you share a vision of harnessing technology to create safer industrial environments, or are interested in staying informed about what we are doing, reach out to us at our website or follow me onTwitter or LinkedIn.

Best Wishes and Happy, Safe, Industrial Workplaces

NEWS

Drones to the rescue - Curiosity Magazine

UAS Startup Apellix Focusing on Dangerous Painting Jobs - UAS Magazine

Airborne Robot Can Replace Ladders in Industrial Environments - Information Week

Apellix Readies Drones for Coatings Industry - Robotics Business Review

How This Drone Company Wants to Clean up Dirty Jobs - UpStart Business Journal

Industrial Drones With Robert Dahlstrom, Apellix - That Drone Show

The Adventure of Drone Sawyer (30 sec video) - Discoveries TV

Apellix Drone Can Paint Homes and De-ice Airplanes - Tech Insider

Apellix is an Exciting Drone for a Boring Job - Popular Science

Drones to Replace Construction Workers? Global Sources Drones & Robotics

Demo of the Apellix Worker Bee Pre-Production Spray Paint System - Apellix Video

#DronesDoGood #DronesSaveLives #GoodIdeas #DronesAreSoftware