Written on the 20th

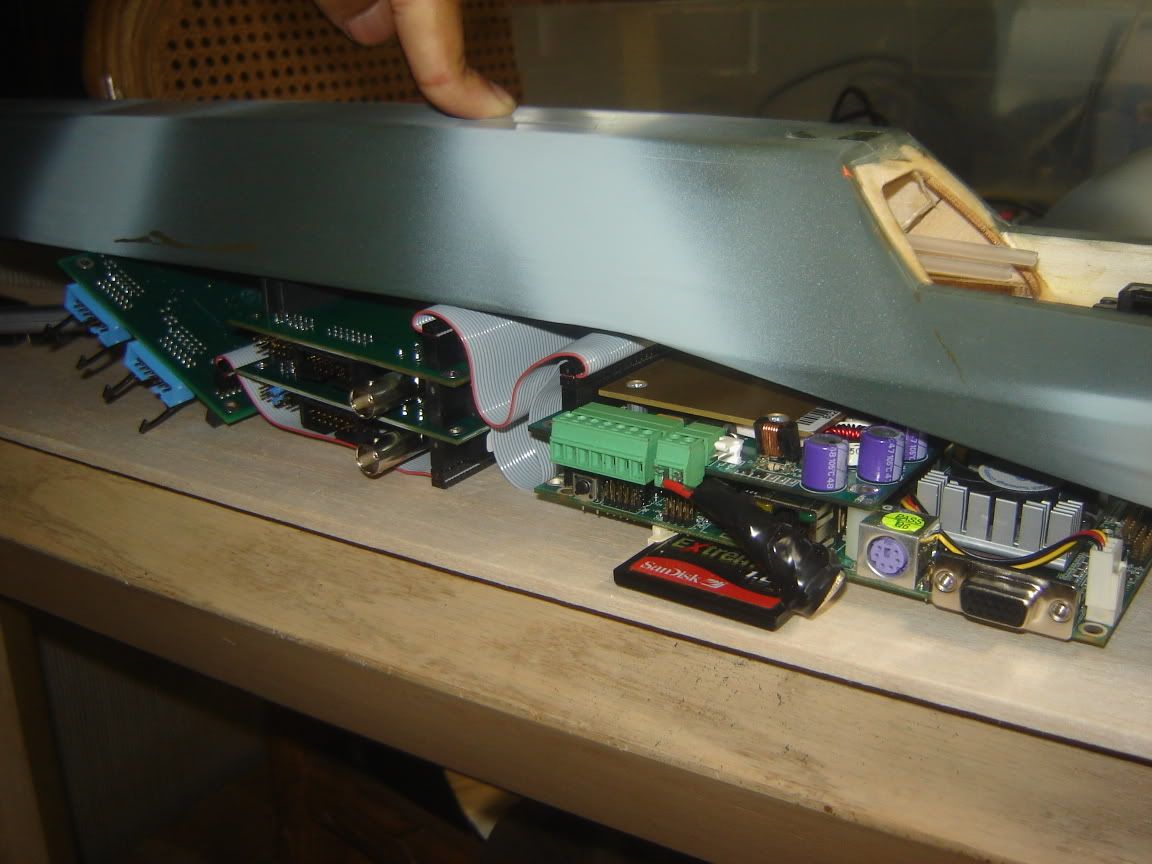

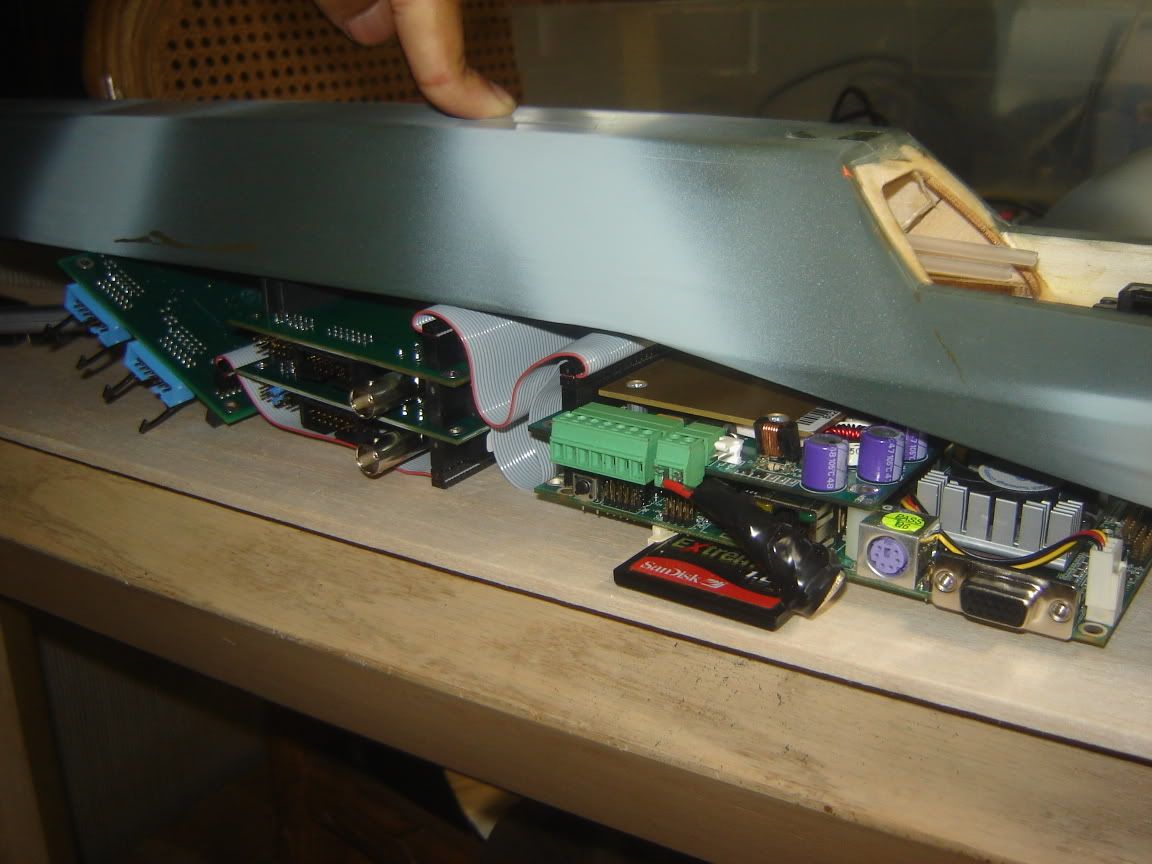

Right now, the computer system is almost complete. After numerous discussions on the phone, PC104 boards were added, omitted, and sometimes stared at blankly. The end result is that there is one more PC104 board that had been expected. I guess it was an acquiesce where I wanted to get USB2.0 and was planning to buy an adaptec PCMCIA adatper to go with a dual PCMCIA PC104 board I had. I then found out that ISA bus only has 15.7Mbytes/s (actual power of 2 value, not some 10 based, rounded one), which, well, is not quite much more than the 12mbps of USB1.1. Saved myself $14. That's a lot of money. That's a V-Tail mixer right there. So in the end, after calling Sensoray, and asking them about the 311 framegrabber, which I have 6 of, it came down that logically I need two to accomplish what I wanted, which was dual video in at 30fps. The tech guy was actually VERY helpful, giving me free software links, such as VLC, and explaining bitrates and memory calculations and what not- even telling me that the USB2.0 idea wouldn't work due to the bandwidth of ISA- which ended up being very, very true after some independent research on my part. End result is this: at the best quaility video, which is 640x480, I get (640x480x(3 pixels for color))/8 bits/bytes= 115,200 bytes per frame. 30 frames each second = 3,456,000bytes per second of memory is needed for each frame grabber, or 6,912,000bytes a second on video alone, maximum. These are actually really high quailty, uncompressed images, so i'm not complaining much, especially since that leaves 9Mbytes/sec to do control a 2 axis stepper motor controller. I think it can manage. And what's my last PC104 board? A power supply. Sure, you might think its a waste of a slot, but its a 50Watt PSU and has power out at +12V, +5V and -12V and -5V. I have no idea what I can use the negative stuff for, but i'm sure i'll have fun trying to find something that needs -5V in. :)Bold idea for video recording...As for software, the Sensoray Support guy told me, that for streaming, I can encode using VLC on the onboard computer and capture using VLC on the client side, while viewing the stream. This helps because VLC is free. I like free. Cheap is good, but free and feature filled rocks. Also, he told me that if I wanted to capture a frame, the sub megapixel raw image data of each frame will be in memory for 1/10th of a sec. This means that I can just copy that memory data form that address to another one to save to the hard drive. This will give me a high resolution picture of what i'm viewing for retrieval while a realtime low resolution stream is simul-cast to the client basestation. I guess I can record the massive ~7Mbyte/second recording of the flight on board as well without killing the computer too much, if I really really wanted to. The good news is that chances are, it won't be that big. The resolution of the camcorder is not VGA. In fact, the FPV CCD has a better resolution and larger CCD than the panoramic view. Also the FPV view isn't going to be as important to me as the panoramic camera, so I can get away with shrinking the view a good bit, to maybe QVGA (320x240x3/8)or a bit under a megabyte per second. What this means, basically is that at my realistic highest quality, i'll probably be looking at 2 to 4Mbytes/s- and that is IF my VIA processor can handle it. Kinda missing Intel or AMD right now...Also on the software side, I will be exploring URBI. After seeing how it functions, and wieghing the pros and the cons, the best I can say is that unless I get the full engine and studio, it will have to be relegated to sending and receiving messages from sensors and MSRS, and some vision tracking. This decisions comes pretty hard after seeing that this software can see where faces are and track points in a video and gives me TCP/IP messaging, but its lack of true NMEA decoding, the 1ms per instruction, the fact that to get the full benefit, and the fact that after a weekend of trying with my friends, we STILL haven't gotten URBI to communicate with the local machine, means that, although its a great piece of software, its not a solid fit for this application, but is a SOLID addition for over network communications.Let's get back to the computer...Samtec sent me the cables, and i'm really happy that I called in the day they were made and asked them to lengthen the cables by 1.5” I should have added another half inch, but whatever. As far as the computer goes, i'm separating it into 3 modules- Computing, Vision, and Motion. This move into modular organization started with the desire to not have a 3” high computer stack and the idea to spread the weight along the fuselage instead of some crazy 1.5-2 pound point mass. Hopefully this helps the plane's structural integrity.I will be running XPlite as certain option I want to play with are found only on XP. Being the resource hog that XP is, once I get everything going well on the system, i'm cutting out almost all the fat I can to make it as memory thrifty as possible. As long as I have a dedicated 15MB of memory for the video saving, 10 for streaming, and 30 for robotic control,g I will be happy. Out of 256MB, that leaves 201 for whatever fluff MS wants to have for .NET, and support services. If this sucker won't cut it, the PC104 devices and all software are cross-platform and should work great on linux, however I really REALLY wanted to play with some topo mapping software on this...The emergency parachute arrived early last week. Its light, looks strong, and took my 30 minutes to untangle. At 54”, it means my plane will hit the ground at ~15 ft/sec in the event that things happened. I haven't decided whether to mount it on the top of the plane, so that it can land on the landing gear, or on the bottom, so if the computing system breaks off if the plane cracks in half, the really good stuff is safe.

As far as the computer goes, i'm separating it into 3 modules- Computing, Vision, and Motion. This move into modular organization started with the desire to not have a 3” high computer stack and the idea to spread the weight along the fuselage instead of some crazy 1.5-2 pound point mass. Hopefully this helps the plane's structural integrity.I will be running XPlite as certain option I want to play with are found only on XP. Being the resource hog that XP is, once I get everything going well on the system, i'm cutting out almost all the fat I can to make it as memory thrifty as possible. As long as I have a dedicated 15MB of memory for the video saving, 10 for streaming, and 30 for robotic control,g I will be happy. Out of 256MB, that leaves 201 for whatever fluff MS wants to have for .NET, and support services. If this sucker won't cut it, the PC104 devices and all software are cross-platform and should work great on linux, however I really REALLY wanted to play with some topo mapping software on this...The emergency parachute arrived early last week. Its light, looks strong, and took my 30 minutes to untangle. At 54”, it means my plane will hit the ground at ~15 ft/sec in the event that things happened. I haven't decided whether to mount it on the top of the plane, so that it can land on the landing gear, or on the bottom, so if the computing system breaks off if the plane cracks in half, the really good stuff is safe.

The GPS I have, the ZYX-GM11-5U, in its shell, is waterproof, magnetic, and heavy. After removing the shell, it became very, very light. However, I just found out that it doesn't have WAAS. I guess I can't complain, as it was a freebie from a trade...Incoming...On order, and incoming, are several support components. The first was the gear system for the stepper motors to actuate the CCD. I had been staring at it for a while, but I didn't want to get it until I had more stuff to buy because there is something about paying more for shipping than for the item that gets under my skin, even if the item is at a steal of a deal price. I did find, Friday, the day I ordered, an identical pitch gear that will let me use my .06”, or 1.59mm, shaft with these gears, which have a 1.9mm bore. In other words, the hole is too big. Also, from surplus she is an acrylic dome. This is appararently clear gold, as, funny enough, these things are HUGE sellers at Surplus Shed and God was good enough to make me wait a day to order the other stuff. I was told that they would sell out in a couple of days and they JUST put them on. The best part is, that it is just the right size for what I wanted to do. The others that used to be on there weren't. Speaking of which, let me get into that...Attached to each stepper motor will be a that gear that fits, which will then spin a 1.9/2.0mm axle and work the Pan and Tilt. To make sure that the stepper motor will be affected by the wieght, or lack there of of the lens system or the whole camera body, I will be using worm gears right after the adapting gear. This means at the high speeds, if I want to do a rapid rotation, the torque of the stepper motor doesn't need to be anywhere as high as it ought to me, which is good because the faster you accelerate your stepper motor, and the faster you go, the lower your torque is. If you accelerate too fast, you can actually skip, or jump steps, making your readings inaccurate. Also, the worm gearing, would allow for precision movements. The stepper motor that I have does 20 full steps per revolution. This means, using ¼ stepping tricks, I have an 80 step resolution per rotation of motor shaft. Gearing it down, depending on which gears I end up deciding to use, I can really rack up the resolution to, hopefully a degree of rotation per step, which is nice. Not bad for a $4 stepper motor system. What makes it really great is that when I program the camera to track a certain GPS location, using the compass and altimeter, it can actuate the camera with pinpoint accuracy. The optical acrylic dome will be used to make sure that no camera motion translates into unintentional rudder motion:)Finally on order is a LM317HV adjustable voltage regulator from Electronic Goldmine. Mark was nice enough to go over how do to the equation, and I have a bread board set up ready to solder when it arrives in a week. This will take the +5V in from the PSU and make it into 3.3V for my logic level converter ($1.95 @ sparkfun), which lets my 5V parallel port talk to my Altimeter with limited fuss. The helping hands that I got from them in my last order was a BIG help thus far with soldering. I've actually grown to enjoy it. I did pick up a small super solar panel just to check it out, for adding solar to future UAVs, and some micro motors that fit on the head of a dime. What will I build with those motors? I have no idea. The they are tiny tiny! Oh, and after I found out that the two funny looking pens in the Big Surprise Box were $70 Gateway Stylii for the Wacom Based Tablet PCs, you know I picked up another one:).Lastly, I have to order the Vtail mixer. MX80, virturally no stepping.I have yet to weigh the computer stuff as it has changed since we started. However, I hope everything will be light. There isn't much fat left to cut. I changed lenses, lowered batteries, adjusted components...there's not much left without throwing out whole assemblies.

As far as the computer goes, i'm separating it into 3 modules- Computing, Vision, and Motion. This move into modular organization started with the desire to not have a 3” high computer stack and the idea to spread the weight along the fuselage instead of some crazy 1.5-2 pound point mass. Hopefully this helps the plane's structural integrity.I will be running XPlite as certain option I want to play with are found only on XP. Being the resource hog that XP is, once I get everything going well on the system, i'm cutting out almost all the fat I can to make it as memory thrifty as possible. As long as I have a dedicated 15MB of memory for the video saving, 10 for streaming, and 30 for robotic control,g I will be happy. Out of 256MB, that leaves 201 for whatever fluff MS wants to have for .NET, and support services. If this sucker won't cut it, the PC104 devices and all software are cross-platform and should work great on linux, however I really REALLY wanted to play with some topo mapping software on this...The emergency parachute arrived early last week. Its light, looks strong, and took my 30 minutes to untangle. At 54”, it means my plane will hit the ground at ~15 ft/sec in the event that things happened. I haven't decided whether to mount it on the top of the plane, so that it can land on the landing gear, or on the bottom, so if the computing system breaks off if the plane cracks in half, the really good stuff is safe.

As far as the computer goes, i'm separating it into 3 modules- Computing, Vision, and Motion. This move into modular organization started with the desire to not have a 3” high computer stack and the idea to spread the weight along the fuselage instead of some crazy 1.5-2 pound point mass. Hopefully this helps the plane's structural integrity.I will be running XPlite as certain option I want to play with are found only on XP. Being the resource hog that XP is, once I get everything going well on the system, i'm cutting out almost all the fat I can to make it as memory thrifty as possible. As long as I have a dedicated 15MB of memory for the video saving, 10 for streaming, and 30 for robotic control,g I will be happy. Out of 256MB, that leaves 201 for whatever fluff MS wants to have for .NET, and support services. If this sucker won't cut it, the PC104 devices and all software are cross-platform and should work great on linux, however I really REALLY wanted to play with some topo mapping software on this...The emergency parachute arrived early last week. Its light, looks strong, and took my 30 minutes to untangle. At 54”, it means my plane will hit the ground at ~15 ft/sec in the event that things happened. I haven't decided whether to mount it on the top of the plane, so that it can land on the landing gear, or on the bottom, so if the computing system breaks off if the plane cracks in half, the really good stuff is safe.

Comments

If you have any other suggestions, let me know. I listen, as you guys know more than me, but i have thought this project out as well :)

I'm sorry, i completely missed your reply. It just occured to me that i did not explain WHY i even HAVE this particular PC104 board. I won it on ebay for $40 shipped. I do some work with SBCs and have a few PC104 boards like that, but this is the first that has such an efficient processor on board. That's actually what got me to even think about this whole project in the first place.

its about 4lbs, maybe 4.5. computer entire system was like 1.5 lbs by itself. Probably 2 and change with all the electronics. battery is 14 oz, and then is plane and engine weight. chute is nearly weightless.

I'll undercarriage things until the worst happens. I've got a few weeks until my code is done. Working on just reading the GPS and displaying it on the screen right now. Later tonight and early tomorrow, i will start on the autonomous GPS part.

You're looking at pretty much everything right there. The optical done for the camera came in today as did the gears. Power stuff will be in later on saturday. solder it up, then finish the plane's basic build. After, its a host of CoG equations. When Craig and i get things settled, i'll move everything over, and use that bad boy as a developer, or sell the frame to someone who needs it more than i.

And I was mistaken about Nano-ITX, you're right that is bigger. But Pico-ITX (not on that diagram) is actually 100mm x 70mm. A bit smaller than PC104.

Here's a more specific example of one: http://www.logicsupply.com/products/artigo

obviously you wouldnt need the case, but it comes bundled with a 60W PSU and 4 USB2.0 ports that shouldnt have any ISA limitations.

I'm sure there are still cases where PC104 is preferable. But in the project I was working on recently we started out planning to use PC104, but really couldnt come up with any good reason why it would work better than the Pico-ITX that costs about a third of the price. It may be worth a look if you ever decide to build a second one. :)

Thanks, I did :). but i required something expandable. Plus those are the board sizes. I'll have an update shortly, this was written last weekend.