Someday in the not-too-distant future, a drone designed by a computer will be flown by a computer. That's Eli D'Elia's dream.

It's a dream he's working to make a reality by partnering with Autodesk to design the Hooligan 1000, among the first entrants in the newly emerging 1,000 mm drone racing class. But racing is just the beginning for D'Elia, a product designer, roboticist, and professional drone operator who has helped to pioneer drone racing as we know it. For him, it's more important that the Hooligan be durable, practical, and easily adapted for use in industry and agriculture, possibly search and rescue, and eventually, mapping and exploration. He envisions a future where drones move not only through the air, but through water and outer space as well. "We're really just in the Kitty Hawk stage of drone development," says D'Elia. "Competition through sports is a great way to test out ideas and get rid of the bad ones."

Letting the Computer Do the Work

"AI-grown, AI-flown," is how D'Elia summarizes his goal. To that end, D'Elia and his partners at Autodesk, Taylor Stein and Daniele Grandi, will use the Autodesk Dreamcatcher generative design system to design the drone's chassis. With generative design, the designer doesn't come up with the actual design, but instead inputs a set of requirements and lets the computer go to work. While still in its infancy, it has already been used to create an experimental automobile chassis and components for commercial aircraft.

After the design is finalized, D'Elia will start working on the AI control system that will steer the craft using 3D photogrammetry and the NVIDIA Jetson TX1 processor. He expects the AI to be able to learn a given racecourse after several test flights, then fly it both with and without human control. But he also wants it to have situational awareness, the ability to identify objects in the air like birds and other drones, and respond appropriately. "We're putting an additional thruster in there to provide a turbo boost at the end of the race," D'Elia says. "I'd like the drone to be able to tell if there's another drone close to it so it knows when to kick that thruster in for some extra speed."

Drones Far and Near

What D'Elia wants to do and what the Federal Aviation Administration (FAA) will permit are two different things, of course. According to current FAA regulations, all drones in the U.S. must have a pilot at the controls and be within the pilot's line of sight. And it may be years before autonomous drones can be flown in civilian airspace simply due to the danger of a drone hurting people, damaging property, or interfering with air flight. "They'll need to do things like employ redundant flight control systems so that, if a propeller goes out, it won't fall out of the sky," says D'Elia.

But there's no question that many people and companies see a future for drone autonomy, both near and far. Amazon is testing delivery by drone in the UK, where more lax regulations permit drones to be operated beyond the pilot's line of sight. Meanwhile, the startup, Zipline, is already using autonomous winged drones to deliver emergency medical supplies to distant communities in rural Rwanda. And companies in the U.S. are petitioning the FAA for waivers to the line-of-sight rule. The first such waiver was granted in August to PrecisionHawk, an aerial data analysis company, after they provided a year's worth of drone flight safety data.

For D'Elia, all of this is interesting, but the truly exciting possibilities lie further afield. He notes that there's already an XPRIZE competition underway to design a drone that can map the ocean floor by itself. D'Elia thinks it's only a matter of time before similar efforts begin to explore outer space.

In the Field and in the Lab

When he's not working on the Hooligan 1000 designs, you'll often find D'Elia flying drones in the vineyards of Northern California. The company he started, Eagle Eye Metrics, deploys drones to help farmers, generally vintners, monitor their crops and map their fields. Using a NDVI camera, his drones capture infrared frequencies that can reveal information about soil quality, pest infestation, and overall plant health. On foot, this kind of necessary recon can take farmers a week. D'Elia and his drones can do it in less than an hour.

When he's not designing drones, Eli D'Elia performs drone-based aerial mapping for farmers in Northern California through his company, Eagle Eye Metrics. / Credit: Eli D'Elia

When he's not designing drones, Eli D'Elia performs drone-based aerial mapping for farmers in Northern California through his company, Eagle Eye Metrics. / Credit: Eli D'EliaD'Elia has always had an interest in both the sport and the practical use of robotics. Long before BattleBots hit the airwaves, he was part of an amateur robotics community in the San Francisco Bay Area in the '90s. They would build their robots during the week, then put them into the arena to do battle on Saturday night. "The whole idea was to one-up whatever the other guy's robot did. If he clobbered you, you hit him with a projectile. If he fired at you, you hit him back with a flamethrower," D'Elia says.

When drones hit the hobbyist market in the mid-2000s, D'Elia was immediately interested. However, he and his frequent collaborator, Marque Cornblatt, saw one big problem: drones were too fragile. "You could spend two weeks and $1000 building a drone, but you can make one mistake and crash it in ten seconds and you're back to square one," D'Elia says.

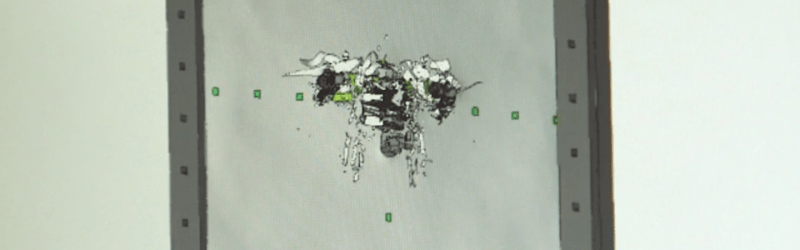

Under the auspices of their own organization, the Aerial Sports League, D'Elia and Cornblatt designed the Hiro, a drone with a monocoque frame made from a lightweight, super-strong polycarbonate used in aerospace and military applications. The design was fireproof, waterproof, and sturdy enough to withstand direct hits from a baseball bat and even a shotgun blast. It was among the first successful drone projects on Kickstarter.

D'Elia and his Autodesk collaborators are currently finalizing design parameters for the Hooligan using Autodesk® Fusion 360™ software, specifying requirements for mounting connections and access ports. When completed, they'll feed the requirements into Dreamcatcher, which will take several weeks to generate designs for the chassis. They'll then print that design in polycarbonate, assemble the components, and take it out for a test flight. Then they'll begin working on the pilot AI with help from NVIDIA.

D'Elia remains upbeat about the near future not only for his project, but for drones overall. "Sometimes you hear people say that all this amazing stuff is going to happen 'in the future,' but you have to remember—that's like three to five years from now," he says. "Think how far self-driving cars have come in five years. This stuff is coming and it's coming fast."

Eli D'Elia and Taylor Stein will be speaking about designing racing drones using Autodesk Fusion 360 software and Flow Design wind-tunnel simulator as part of Autodesk University 2016 in Las Vegas, November 15-17. Learn more and register today.