New rules from the DOT concerning airtravel and LiPo batteries. Thank goodness we have reliable Plastic Bags to protect us!!

;-)

Paul

First I must thank Jeffrey Johnson who posted a set of images of the Cularis he is building for photo mapping. He has made a really neatmodification by moving the rudder and elevator servos from the stockposition in the cockpit, to tail mounting in the fuselage. Not onlydoes this free up space in the cockpit area, which will make it easierto enlarge to take the camera, but it also moves some 35gm of weightto the rear. This should greatly help in balancing the plane withoutadding too much lead.

I have also now read some 670 posts in the Cularis building thread on the rcgroups forum. There is a wealth of good stuff there, includinga number of modifications to the stock kit to improve performance and ease of use. Specifically, I now plan to do the following.

There is one other modification that I am in two minds about and that is a secondary means of fixing the wings. In the stock kit, the wings areheld in place with plastic catches. These are design to open in theevent of a heavy landing so that the wings break away. If wouldseem, however, that some have opened in flight leading to spectacularcrashes. Jeffrey has a a similar modification to several shown inthe thread that involve using a secondary pin through the wing root.While this will certainly keep the wings solidly in place, I am notsure if it is better or worse in the case of a bad landing.

Building a UAV for phot mapping - Previous Posts

Ahh!! CRASH and BURN!!

I had planned to use the Pico-Pilot and Pico-GPS for the autopilot in my UAV, but I have now discovered that since Jan 2007, they have been classed as MILITARY technology and are controlled by US Export License regulations. Specifically theregulations cover,

a. “UAVs” having any of the following:

a.1. An autonomous flight control and navigation capability (e.g., an autopilot with an Inertial

Navigation System); or

a.2. Capability of controlled flight out of the direct visual range involving a human operator

(e.g., televisual remote control).

b. Associated systems, equipment and components as follows:

b.1. Equipment specially designed for remotely controlling the “UAVs” controlled by 9A012.a.;

b.2. Guidance or control systems, other than those controlled in Category 7, specially designed for

integration into “UAVs” controlled by 9A012.a.;

b.3. Equipment and components specially designed to convert a manned “aircraft” to a “UAV”

controlled by 9A012.a.

Note: 9A012 does not control model aircraft.

Despite the last sentence, UNAV, who make the Pico Pilot have now told me that none of the applications for export licenses they have made thisyear have yet been granted. Back to the drawing board.

The other common low cost option for an autopilot seems to be based on the FMA Co-Pilot for flight stability with an additional board suchas the RCAP2 plus a GPS receiver for navigation. While a cheaperalternative, I had already discounted this approach because it isbased on thermopile sensors. For my terrain, I cannot get a clear360degree view of the horizon to calibrate the system before launch.In addition, the various different terrain types , forest, grassland,lakes etc. could give problems in flight, irrespective of thetemperature differences that can occur if different parts of a valleyare in sunlight or shade.

During my initial research into autopilots, I also looked at the Paparazzi project. While there is a wealth of open source stuff there, thecurrent Tiny autopilot still uses thermopile sensors for stability,although it does have an on board GPS unit for navigation. An all singing, dancing IMU with gyro's , mangetometers etc. is under development. Althoughall the designs are published, there is still no commercial source ofassembled units or PCB's.

A recent post on this forum (can't find it now), talked about the the UAV development board from Sparkfun. I had a brief look at this, butinitially discounted as they claim that the firmware is a guidelineonly. It is also written in assembly code and I am far to old tostart writing in assembler again. Still I shall have another look atthis over Christmas, as the board does have a proper IMU with 2 gyrosand a 3 axis accelerometer.

Conclusions and Questions

The first image shows the recommended distribution of components for the electric version of the Cularis. (Click for higher resolution). In this configuration, the plane balances at the CGO with 3 weights (supplied in the kit) fixed under the tail plane. The component weight budget is

This gives a total of 670gm. The manufactures claim an all up weight of 1680gm with a wing loading of 30.5g/dm2.

In this image, I have added the Pentax A30 camera and a PicoPilot with PicoGPS. The camera is about 8mm wider than the center opening in the fuselage, so I will have cut back the sides for it to fit. I will also machine out a stepped hole in the base for the extended lens to sit in and see through. If I try to locate the camera further back, then I will have to machine out the two servo openings as well.

The addional weight is

However, I think the real problem is not the weight but the COG. A simplified calculation of the moments of the camera, the autopilot and the new position of the Tx about the COG, suggest that I will have to add about 70gm to the tail in order to bring the plane back into balance. So the total additional weight will be in the order of 283gm. This will increase the all up weight to 1963gm with a 16% increase in wing loading to 35.6g/dm2.

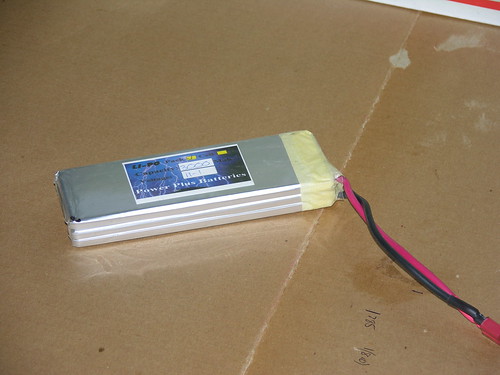

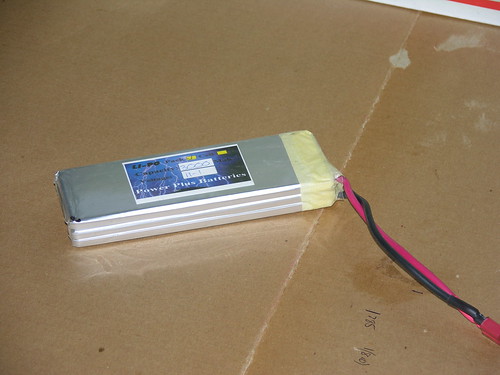

Although it may be standard practice, I am not really happy about have separate Fight and RX batteries. There are two things to charge and check before each flight and it just seems more elegant to have a single power source with a switch mode SportsBEC. With some searching, I found a DuraMax UltraPro 3s 3600mA Li-po with a flat form factor. The dimensions are 145mm x 50mm x 16.2mm. With a small amount of machining, this will fit in the space previously occupied by the Rx battery. The weight at 280gmplus a Sports BEC is only 35gm more than the previous batteryconfiguration. The real gain is in the balance, as the new heavierbattery is behind the COG.

By moving the Rx and autopilot back as shown, the balance weight reduces to 25gm, so in all this solution is a little lighter than the previous one and I get more battery power

our bird the A-3

yamaha R-MAX flown by georgia tech

taken with 7mgp camera and own design foamy

marymoor rc park

sweet uav !!

I have bought a Pentax Optio A30 to use as my aerial camera. It is similar to a number of the latest generation of sub-compact 10Mpixel cameras and has good reviews, especially in terms of its image quality. It weighs about 160gm with battery and SD memory card and at 58mm,has one of the smallest widths I have found – important for fittinginto the Cularis body.

The highest resolution image is quoted as 3648 x 2736 pixels. Based on the handbook, a 4Gbyte SD memory card at the best quality jpeg setting, should give about 1200 images. The camera has a continuous mode where images are taken and downloaded to the SD card as fast as possible as long as the shutteris pressed. One option for using the camera in the UAV, is to set itrunning in continuous mode and then select 1 in n of the imagesproduced to make the photo-composite.

With a fully charged battery, I tested the camera in continuous mode while photographing a clock. The camera managed to capture 1613 images at full resolution in high quality mode in 23 minutes before filling the 4Gbyte SD card. The battery indicator showed about half full at the end of the run.Although the average interval was about 1.2 seconds, there were somegaps between images of up to 8 seconds and in other cases, 2sequential images showed the same time. Both results suggest thatthe timing is not constant, but is a function of the amount of datathat needs to be stored on the card. The review also states that thefile size varies a lot depending upon the image content, so this makematters worse.

I then tried taking photos at timed intervals. I could get down to about a 4 second interval with only an occasional missed image, although this may have been finger trouble. So if I want images taken at regular, known intervals, I will have to use a servo driven IR interface such as the PRISM.

Now to look at flying the camera. There are two limiting scenarios.

Comments and Questions.

Surprisingly, Atkins adds that during takeoff, the UAV is blind. “The plane takes no measurements of its surroundings. The waves would confuse it. ‘Most people wouldn’t do it this way,’ Atkins said. ‘The plane puts the motors on at full throttle and sets the pitch elevator enough to break out of the water. Then it counts and pitches forward. We believe that if we had done it any other way, we would have basically dived into the ocean on takeoff because the plane would have detected huge oscillations due to the waves.’”

And here's an interesting observation from the project's home page:NASA is developing a navigation system that augments GPS signals via a satellite phone network so that it works around the globe, beyond the limited implementation of WAAS. Their intended application is a UAV based mapping function utilizing synthetic aperture radar technology which requires a highly stable and accurate platform.

For testing purposes they will mount the radar and navigation system on a Gulfstream III (I especially like this part), "Since the Gulfstream III operates outside civilian air space it will not need a permit to use the UAV which takes 90-days due to a somewhat archaic processing system." I guess we're not the only ones frustrated with the FAA, even the best & brightest at NASA have a hard time with the red tape!

For details see article:

Nasa Develops Highly Accurate Plane Nav System

The PPA system will help keep the C-20A Gulfstream III flying level so the UAVSAR radar pod can scan geoseismic hot spots.

[UPDATED: paper is finished and available below]

I've put together a technical assessment white paper for the FIRST robotics league, proposing an indoor aerial robotics contest for 12-17 year old kids (and coaches). Target price is under $1,000 and safety is of prime importance. This paper lists the possible platforms--microplanes, helis, quadcopters and blimps--and discusses the pros and cons of each. At this point I've tried most of the options, from helicopters to quadrotors to blimps to ultralight planes and I'm leaning towards quadcopters and blimps as the best choice.

Cost, simplicity and safety pushed me towards the blimps, but I'm concerned about having the kids having to build the autopilot from scratch. Check out the draft of my white paper and tell me what you think.