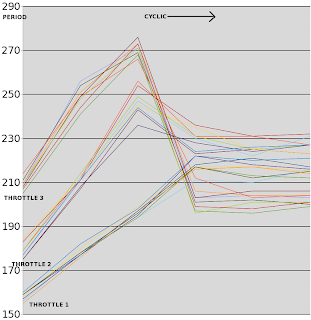

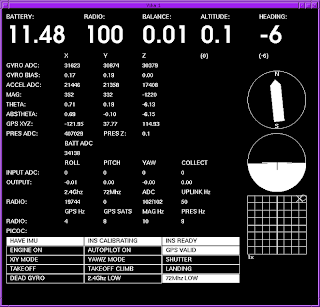

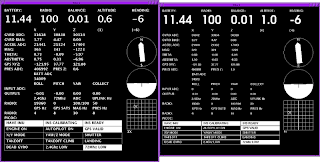

Made a program that spun Marcy 1 in a variety of throttle & cyclic settings, to measure the effect of cyclic on period.

Regardless of battery charge & battery weight, period for every throttle & cyclic had roughly the same curves. Subsequent test runs got amazingly similar results. The only thing affecting period was PWM.

That was subtracting cyclic from throttle to flatten the curve, but it did the opposite. What seems to be happening is cyclic subtracting more throttle than it's adding which causes RPM to go down.

Then the throttle hits minimum on the subtracted side, but keeps adding cyclic on the added side, which causes RPM to go up. Then we're hitting the limit on the active side & the inactive side for all greater cyclic, so RPM is constant.

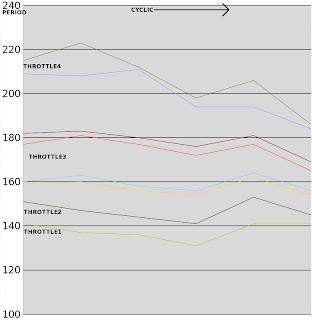

Adding straight cyclic to straight throttle gave more consistent RPM curves.

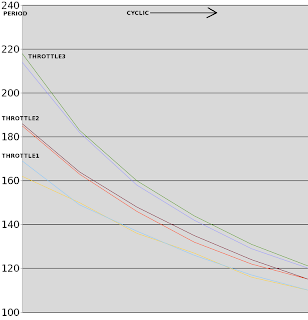

Another algorithm which just subtracted exactly as much cyclic as it added, with the maximum determined by total throttle got pretty flat curves.

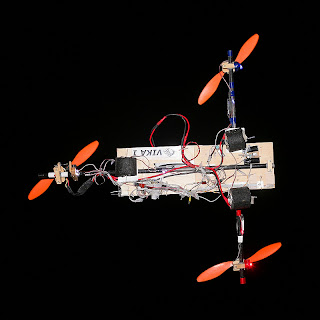

Even if we can't fly anywhere, the test jig did show some usefulness. The next great task is making a test jig for altitude.

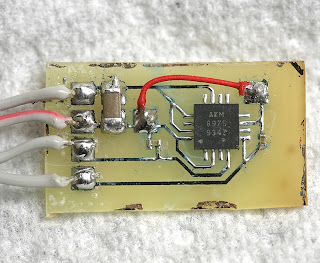

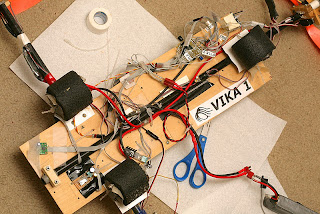

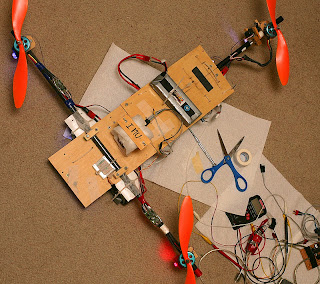

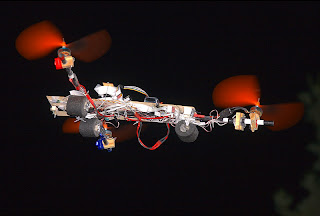

Then, there was this thing from many months ago.

Thought it could be used as a super cheap airfoil in a monocopter. It

would be limited to the smallest power system. The torque would destroy it. The motor would have to be mounted on it. Extra weight would be required on the balance beam.

Lowpass vs averaging notes

After 3 years involved in the subject, we now think averaging is a better deal than lowpass filtering. Lowpass filtering is supposed to remove aliasing, but for all the talk of aliasing, let's consider the disadvantages.

The lowpass filter doesn't buy anything else except removing aliases. A simple, 1st order lowpass filter is not going to chop off exactly at the nyquist frequency. It needs to remove way below the nyquist frequency before all the aliases are truly gone. Finally, it takes a lot of fixed point spagetti code if you want it to work fast, without an FPU.

The lowpass filtering we've used has probably not been as good as the averaging we used before. It's probably caused more oscillation by increasing lag time than averaging caused by letting aliases pass through.

Having said that, the damping foam & ballast we use has allowed the lowpass filter to pass 1/8 its bandwidth in the roll & pitch direction, while passing 1/4 its bandwidth in the yaw direction. That's just as good as averaging, so we're not inclined to change it.

145Mhz radio notes

Some ideas for a voltage controlled oscillator came to mind. Basically, fabricate a multivibrator which can get in the 145Mhz range. Feed a counter with it & have a microprocessor PWM the input voltage. That might get close enough to use only a 256khz ADC.

Common transistors only get 2:1 gain at 150Mhz. The counter would need a high voltage swing. Just don't have enough instrumentation to test the thing. Something could certainly be built in the 1Mhz range, just to test software radio.

What you want is the AD9552, a frequency up converter. That can generate exactly 145.8Mhz for $14. Nothing is cheap in this business. Anything providing decent reception is going to be comparable to a $100 scanner.

This operation has little point. The ISS broadcasts a repeating morse code beacon. You'd get it for 30 minutes per orbit. There was more point in the trapezoidian equatorial mount. That produced images.