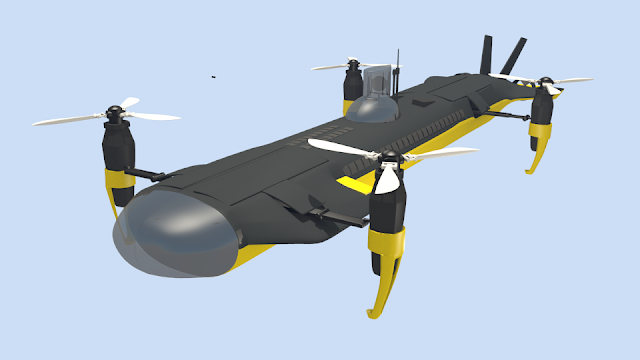

There are individuals who push tools, materials, and craftsmanship to the limit in the world of micro RC aircraft, and [Martin Newell] gives some insight into the kind of work that goes into making something like a 1:96 scale P-51 Mustang from scratch. The tiny plane is 100% flyable. It even includes working navigation lights and flashing cannons (both done with 0402 LEDs) and functional, retractable landing gear. It weighs an incredible 2.9 grams. Apart from the battery, everything in the plane was built or assembled from scratch. A video is embedded below.

[Martin] shares some of the techniques that went into the many specialized parts of the plane. Two documents (Part 1 about techniques used for small aircraft and Part 2 about the P-51 Mustang pictured) are worth a read. In true craftsman fashion, he’s aware that while he rolled his own solutions and wasn’t aware of any similar prior work, he would be surprised if none of his innovations had ever been done by someone else before.

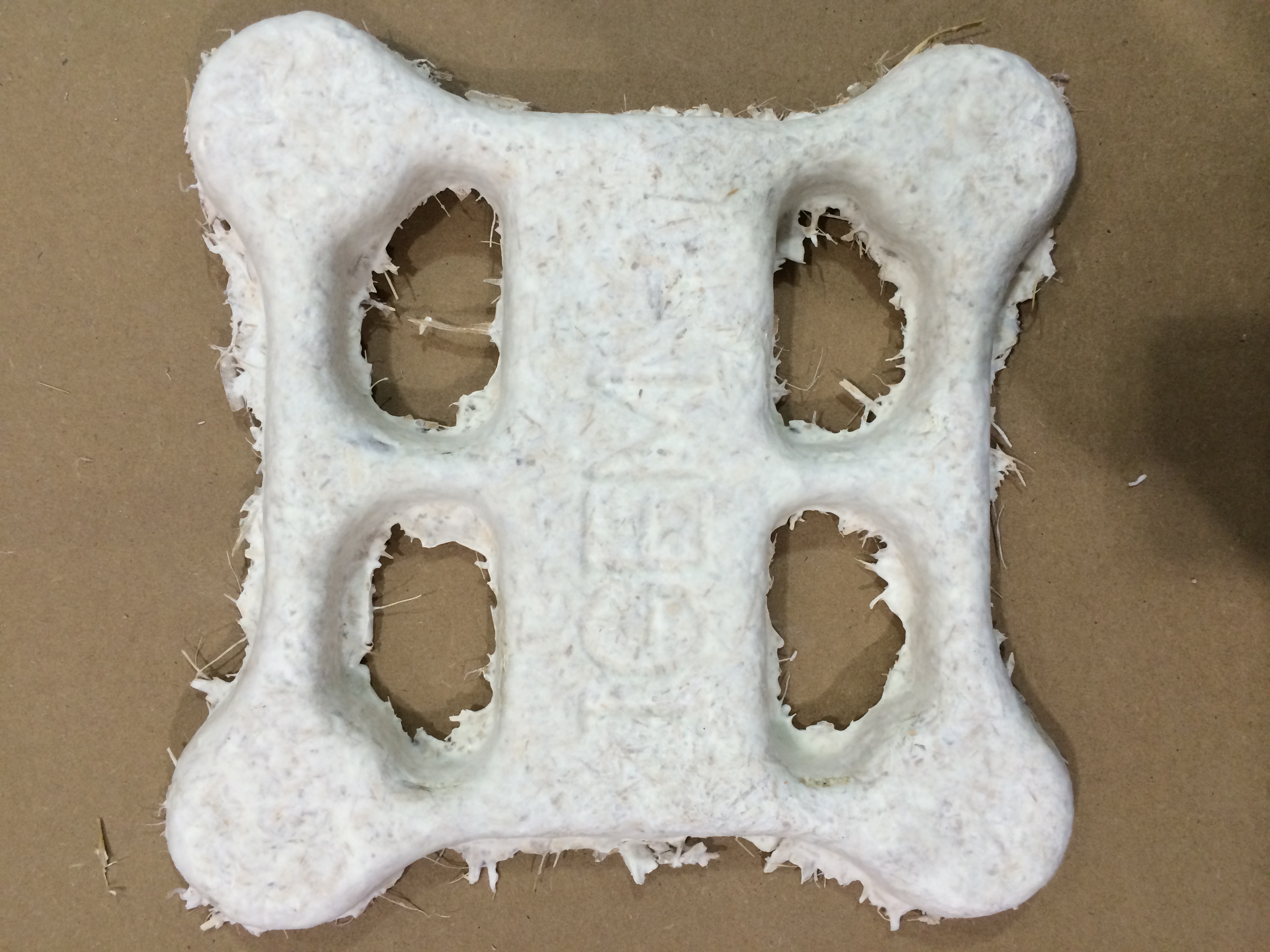

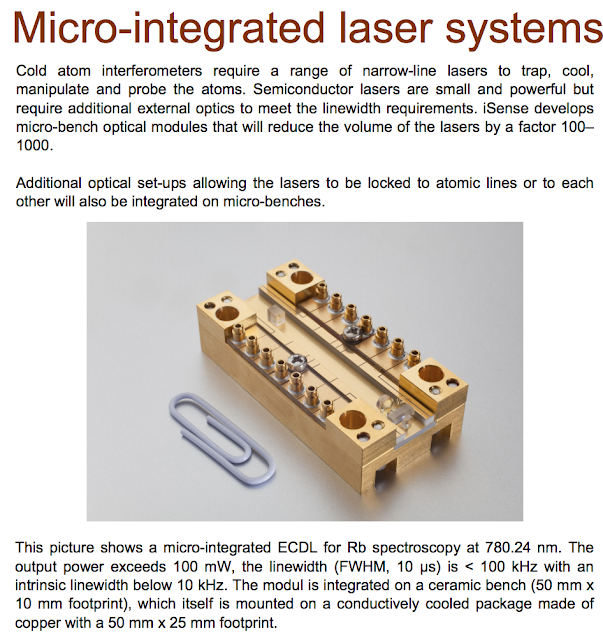

At such small scales many problems need re-solving, like electrical connectors. All the usual off-the-shelf connectors are far too big or heavy to go on such a small device where every fraction of a gram counts. Whenever possible, connectors are avoided entirely but sometimes — like to connect the custom-wound motor — it needs to be done. In these cases [Martin] made his own.

The pin on the left of the photo above is made from a 0.1″ length of 0.010″ diameter brass rod soldered to a wire lead, supported with 0.020″ ID heat shrink tubing. The socket on the right is a 0.1″ length of plastic insulation from 32 AWG wire, with the strands from the other wire drawn through and around, and covered with 0.020″ shrink tubing. Contact is made by the brass pin (left) being squeezed against the multiple strands inside the plastic insulation tube (right).

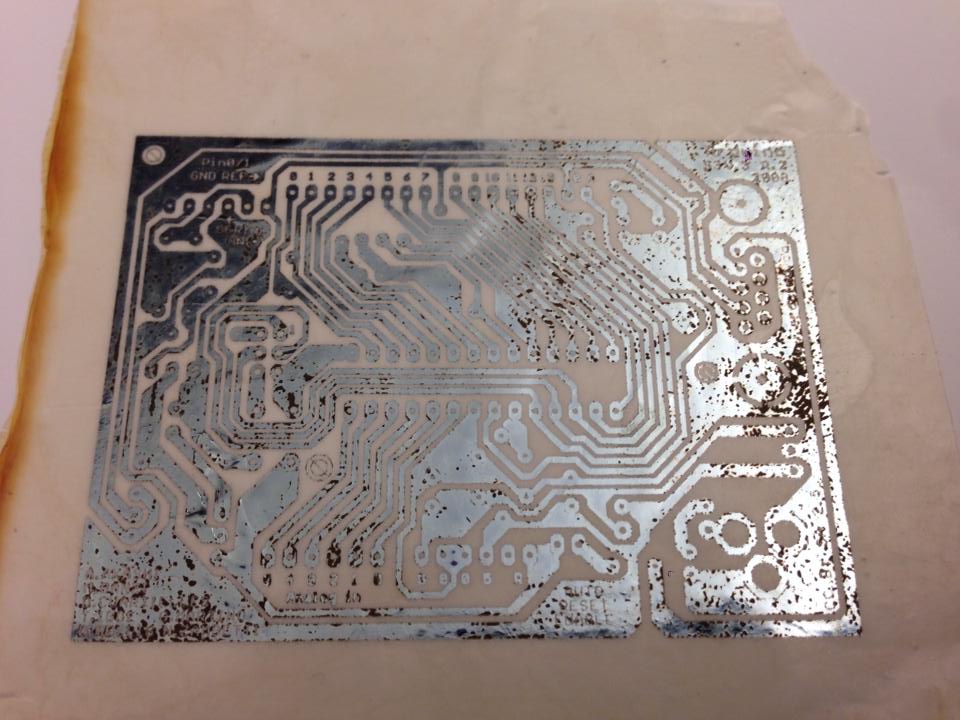

Another innovation was hinges for the control surfaces like the rudder, ailerons, and flaps. Unsatisfied with plastic hinges, [Martin] made his own nearly-frictionless and nearly-weightless ones complete with re-centering springs. Each weighs 1.6 milligrams.

Control surface hinge design [Source: Warbirds at 1:100 Scale by Martin Newell]

Control surface hinge design [Source: Warbirds at 1:100 Scale by Martin Newell]The hinges on the left are made from 0.008″ nickel wire and a 1 mm length of 0.4 mm plastic tube. The centering spring is a nylon bristle from a paintbrush, which [Martin] observed was pointed on one end and seemed quite springy. The tip of a single bristle is inserted into the model and by adjusting how far it is inserted, the amount of maximum deflection the control surface is allowed can be controlled. Once satisfactory, it is secured with a tiny bead of glue.

![[Source: microflierradio.com]](https://hackadaycom.files.wordpress.com/2017/01/actuator.jpg?w=800)

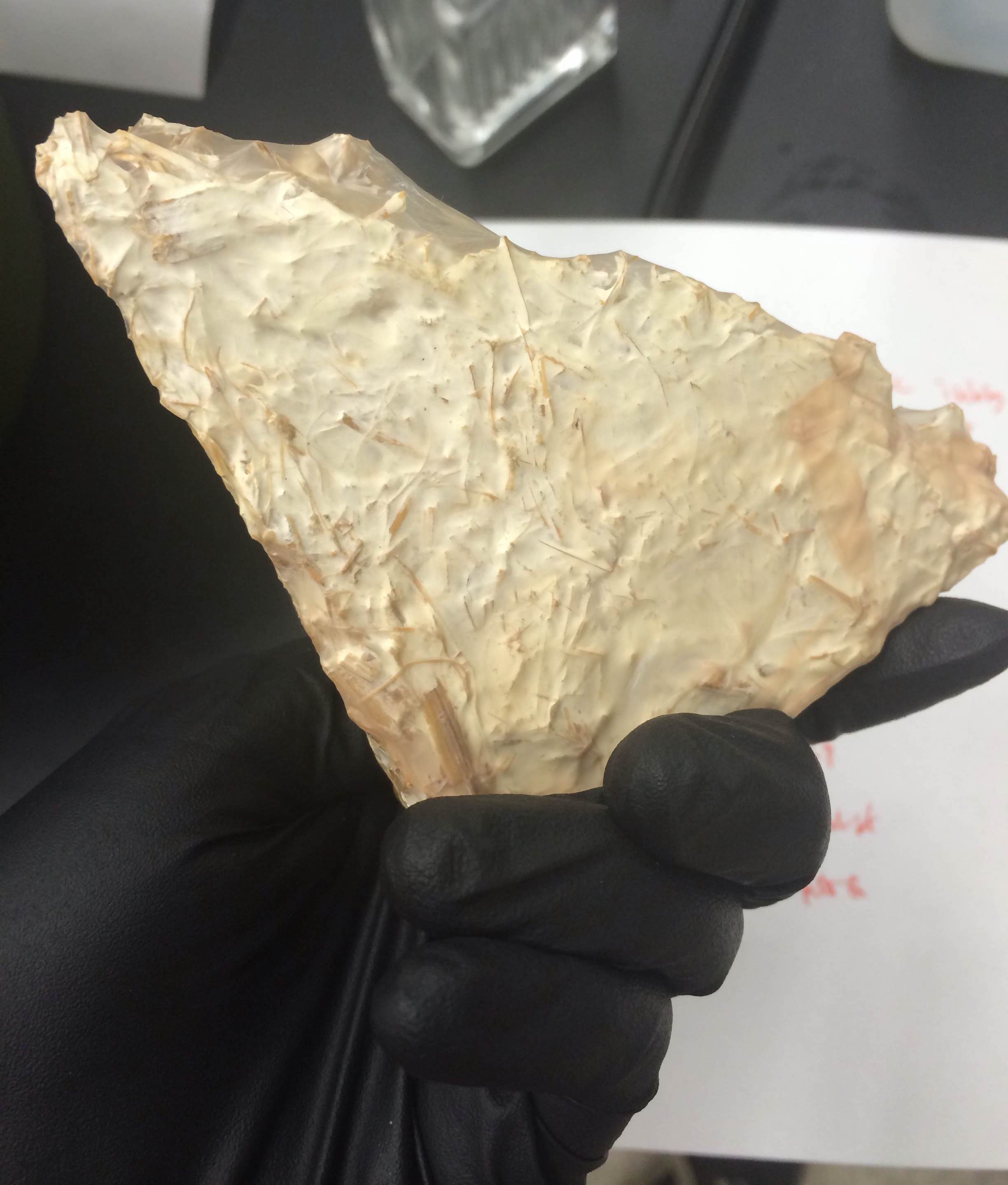

Servos are the usual means of actuating control surfaces like rudders and ailerons on model aircraft, but a plane like this one is far too small and lightweight to carry even the smallest servo. Instead of servos, these micro aircraft use tiny coils and magnets as actuators. They exert no force unless active, which means that whatever control surfaces they connect to need to provide their own means of re-centering and holding stable when idle. This type of actuator is common in micro aircraft, but understanding the design gives insight into why [Martin] designed the hinges and centering springs the way he did. Similar actuators are visible on the bottom of the wings in the video embedded below. They are responsible for moving the two ailerons, and the two flaps. More are present on the rudder and elevator at the rear of the plane.

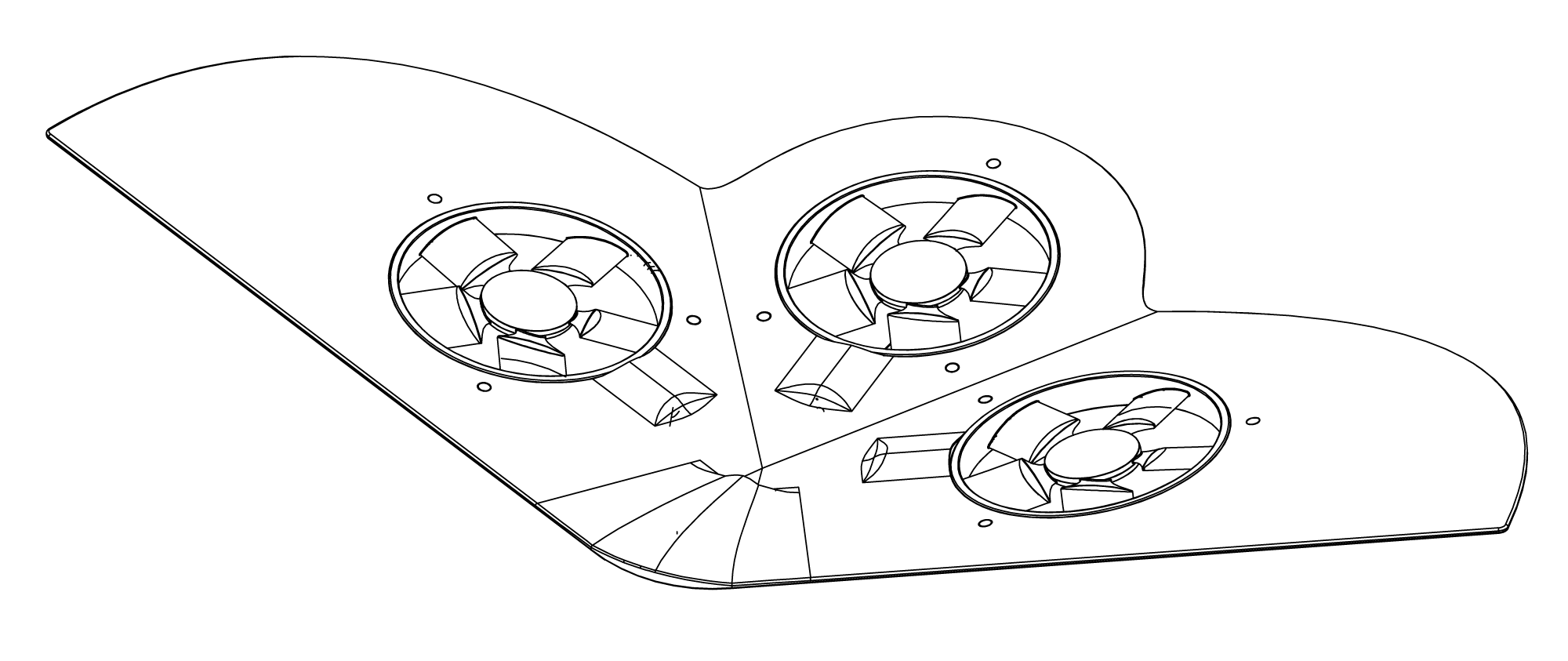

[Martin] says that by far the most difficult part was the retractable landing gear. The solution uses 0.001” diameter Nitinol muscle wire. Muscle wire can be stretched about 5%, then when it is heated above a critical temperature by passing a current through it, it exerts a considerable force in attempting to contract back to its original length. By using two lengths of muscle wire, a pull-pull mechanism can be built in which the contraction of one wire has the effect of stretching the other while either raising or lowering the landing gear at the same time.

A push-pull system using nitinol “muscle” wire provides the raw power behind actuating the landing gear, but required a significant custom assembly to work.

A push-pull system using nitinol “muscle” wire provides the raw power behind actuating the landing gear, but required a significant custom assembly to work.However, that was much easier said than done. [Martin] explains:

“Unfortunately this appealingly simple mechanism is fraught with implementation issues when trying to meet the design requirements. One of them is that after stretching one wire by contracting the other, when the current is stopped the contraction recoils about 30%. Therefore a lock is needed to keep the wire fully stretched. Then a second lock is needed to secure the landing gear up or down, so that sharp sideways forces do not result in any forces back on the muscle wire, which could collapse the landing gear. These requirements were met with a unit that weighs about 400 milligrams. The muscle wires rotate a 0.030” diameter capstan 90 degrees. The muscle wire recoil is countered by an over-center spring acting on an idler at the end of an arm attached to the capstan.”

[Martin] goes into detail about the whole retract assembly for the landing gear in Part 2 of his documentation.

A familiar question has been whether these planes are available for sale. The answer is probably also familiar to people who make such labor-intensive things: [Martin] says they are not for sale, at least not from him. If he did offer them for sale, nobody would pay the price he would ask because of the amount of work involved.

It took [Martin] about a year to develop and build the 1:96 P-51D Mustang, and he just recently shared a video of the tiny plane flying on his YouTube channel. It is embedded below.

[Martin] demonstrates all 8 channels of control in the video below:

Speaking of scratch-built RC aircraft, we previously covered a project dedicated to 3D printing parts for a flying RC plane, complete with in-depth testing and analysis. RC hobby aircraft is an example of a field that, while filled to the brim with off-the-shelf systems, is nevertheless home to individual innovation and DIY spirit.

taken from here

/cdn0.vox-cdn.com/uploads/chorus_asset/file/6030033/Screen_Shot_2016-02-11_at_9.05.27_AM.0.png)