All Posts (14054)

BTW, if you want a more traditional high-wing trainer as a UAV platform, while still made out of the virtually unbreakable Mutiplex elastopore foam, you might be interested in its new Mentor (shown below). It's got a 65" wing, and seems perfect for UAV purposes; indeed Jordi and I saw a few used for just that at the AUVSI show.

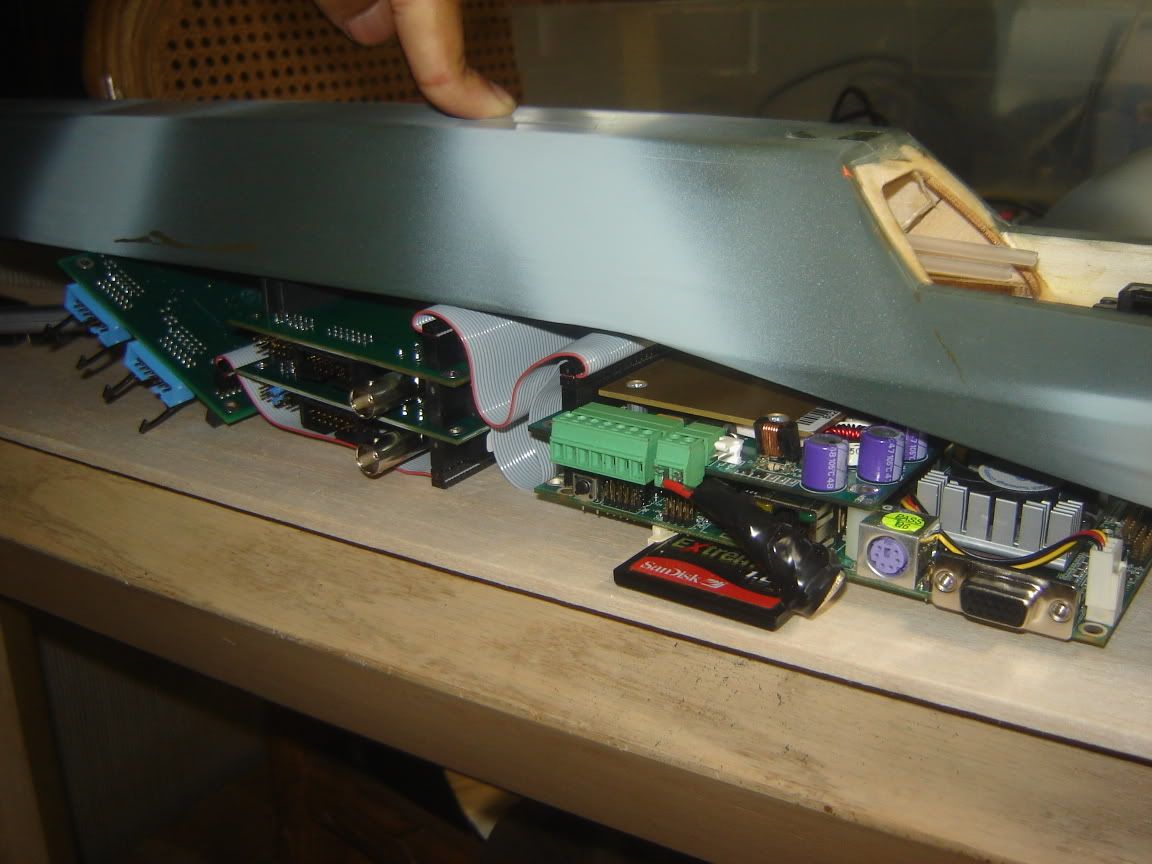

As far as the computer goes, i'm separating it into 3 modules- Computing, Vision, and Motion. This move into modular organization started with the desire to not have a 3” high computer stack and the idea to spread the weight along the fuselage instead of some crazy 1.5-2 pound point mass. Hopefully this helps the plane's structural integrity.I will be running XPlite as certain option I want to play with are found only on XP. Being the resource hog that XP is, once I get everything going well on the system, i'm cutting out almost all the fat I can to make it as memory thrifty as possible. As long as I have a dedicated 15MB of memory for the video saving, 10 for streaming, and 30 for robotic control,g I will be happy. Out of 256MB, that leaves 201 for whatever fluff MS wants to have for .NET, and support services. If this sucker won't cut it, the PC104 devices and all software are cross-platform and should work great on linux, however I really REALLY wanted to play with some topo mapping software on this...The emergency parachute arrived early last week. Its light, looks strong, and took my 30 minutes to untangle. At 54”, it means my plane will hit the ground at ~15 ft/sec in the event that things happened. I haven't decided whether to mount it on the top of the plane, so that it can land on the landing gear, or on the bottom, so if the computing system breaks off if the plane cracks in half, the really good stuff is safe.

As far as the computer goes, i'm separating it into 3 modules- Computing, Vision, and Motion. This move into modular organization started with the desire to not have a 3” high computer stack and the idea to spread the weight along the fuselage instead of some crazy 1.5-2 pound point mass. Hopefully this helps the plane's structural integrity.I will be running XPlite as certain option I want to play with are found only on XP. Being the resource hog that XP is, once I get everything going well on the system, i'm cutting out almost all the fat I can to make it as memory thrifty as possible. As long as I have a dedicated 15MB of memory for the video saving, 10 for streaming, and 30 for robotic control,g I will be happy. Out of 256MB, that leaves 201 for whatever fluff MS wants to have for .NET, and support services. If this sucker won't cut it, the PC104 devices and all software are cross-platform and should work great on linux, however I really REALLY wanted to play with some topo mapping software on this...The emergency parachute arrived early last week. Its light, looks strong, and took my 30 minutes to untangle. At 54”, it means my plane will hit the ground at ~15 ft/sec in the event that things happened. I haven't decided whether to mount it on the top of the plane, so that it can land on the landing gear, or on the bottom, so if the computing system breaks off if the plane cracks in half, the really good stuff is safe.

Bart Remes and his team at the Technical University of Delft have just produced the smallest-ever flapping wing robot (ornithopter) with a built-in camera.With a wingspan of just 10 centimetres (4"), the DelFly could easily be confused with a real dragonfly. Not yet autonomous, but a good candidate for a mouse-chip optical flow autopilot. (Thanks to Protein for the tip)

This is a glossary of some of the terms you may read on DIY Drones. Please feel free to suggest others in the comments below!

- 2.4 Ghz: The frequency used by digital (spread spectrum) radio communications in our applications, including 2.4Ghz RC, bluetooth and some video transmission equipment. This is a different band than the older 72 Mhz band that is used for analog RC communications. To avoid radio frequency conflict is it often a good idea to use 72 Mhz radio equipment when you are using 2.4 Ghz onboard video transmitters, or use 900 Mhz video when using 2.4 Ghz RC equipment.

- AHRS: Attitude and Heading Reference System. See explanation here.

- AMA: Academy of Model Aeronautics. The main US model aircraft association. Generally hostile to amateur UAVs, which are banned on AMA fields. But each AMA chapter and field may have slightly different policies, and it's possible to test airframes and some technology on AMA fields without violating the association's rules.

- APM: ArduPilotMega autopilot electronics

- ArduCopter: Rotary-wing autopilot software for the APM and Pixhawk electronics

- ArduPlane: Fixed-wing autopilot software for the APM and Pixhawk electronics.

- ArduPilot: The overall autopilot project that ArduCopter, ArduPlane, and ArduRover live within

- ArduRover: Ground and water autopilot software for the APM and Pixhawk electronics

- Arduino: An open source embedded processor project. Includes a hardware standard originally based on the Atmel Atmega (and other 8-bit) microprocessor microcontroller and necessary supporting hardware, and a software programming environment based on the C-like Processing language. Official site is here.

- BEC: Battery Elimination Circuit. A voltage regulator found in ESCs (see below) and as a stand-alone product. Designed to provide constant 5v voltage for RC equipment, autopilots and other onboard electronics.

- BASIC Stamp: A simple embedded processor controller and programming environment created and sold by Parallax. Often used to teach basic embedded computing and the basis of our autopilot tutorial project. Parallax also makes the very capable Propeller chip.

- Bluetooth: A wireless technology standard for exchanging data over short distances (using UHF radio waves in the ISM band from 2.4 to 2.485 GHz) from fixed and mobile devices, and building Personal AreaNetworks (PANs). Originally conceived as a wireless alternative to RS-232 data cables. It can connect several concurrent devices.

- Bootloader: Special code stored in non-volatile memory in a microprocessor that can interface with a PC to download a user's program.

- COA: Certificate of Authorization. A FAA approval for a UAV flight. See this for more.

- Eagle file: The schematic and PCB design files (and related files that tell PCB fabricators how to create the boards) generated by the free Cadsoft Eagle program. This is the most common standard used in the open source hardware world, although, ironically, it's not open source software itself. Needless to say, this is not optimal, and the Eagle software is clumsy and hard to learn. One hopes that an open source alternative will someday emerge.

- DCM: Direction Cosine Matrix. A algorithm that is a less processing intensive equivalent of the Kalman Filter. See this for more.

- DSM / DSM2 / DSMX: Spektrum, an RC equipment maker, refers to their proprietary technology as "Digital Spectrum Modulation." Each transmitter has a globally unique identifier (GUID), to which receivers can be bound, ensuring that no transmitter will interfere with other nearby Spektrum DSM systems. DSM uses Direct-Sequence Spread Spectrum (DSSS) technology.

- DSSS: Direct-Sequence Spread Spectrum is a modulation technique. As with other spread spectrum technologies, the transmitted signal takes up more bandwidth than the information signal that modulates the carrier or broadcast frequency. The name 'spread spectrum' comes from the fact that the carrier signals occur over the full bandwidth (spectrum) of a device's transmitting frequency..

- EEPROM: Electonically Erasable Programmable Read Only Memory. A type of non-volatile memory used in computers and other electronic devices to store small amounts of data that must be saved when power is removed, e.g.,static calibration/reference tables. Unlike bytes in most other kinds of non-volatile memory, individual bytes in a traditional EEPROM can be independently read, erased, and re-written.

- ESC: Electronic Speed Control. Device to control the motor in an electric aircraft. Serves as the connection between the main battery and the RC receiver. Usually includes a BEC, or Battery Elimination Circuit (BEC), which provides power for the RC system and other onboard electronics, such as an autopilot.

- FHSS Frequency-Hopping Spread Spectrum is a method of transmitting radio signals by rapidly switching a carrier among many frequency channels, using a pseudorandom sequence known to both transmitter and receiver.advantages over a fixed-frequency transmission: Advantages: 1. Spread-spectrum signals are highly resistant to narrowband interference. The process of re-collecting a spread signal spreads out the interfering signal, causing it to recede into the background. 2. Spread-spectrum signals are difficult to intercept. A spread-spectrum signal may simply appear as an increase in the background noise to a narrowband receiver. An eavesdropper may have difficulty intercepting a transmission in real time if the pseudorandom sequence is not known. 3. Spread-spectrum transmissions can share a frequency band with many types of conventional transmissions with minimal interference. The spread-spectrum signals add minimal noise to the narrow-frequency communications, and vice versa. As a result,bandwidth can be used more efficiently.

- FPV: First-Person View. A technique that uses an onboard video camera and wireless connection to the ground allow a pilot on the ground with video goggles to fly with a cockpit view.

- FTDI: Future Technology Devices International, which is the name of the company that makes the chips. A standard to convert USB to serial communications. Available as a chip for boards that have a USB connector, or in a cable to connected to breakout pins.

- GCS: Ground Control Station. Software running on a computer on the ground that receives telemetry information from an airborne UAV and displays its progress and status, often including video and other sensor data. Can also be used to transmit in-flight commands to the UAV.

- GIT: A version control system for software developers. The DIY Drones team use a Git-based service called GitHub.

- Hardware-in-the-loop simulation: Doing a simulation where software running on another computer generates data that simulates the data that would be coming from an autopilot'’s sensors. The autopilot is running and doesn't "know" that the data is simulated, so it responds just as it would to real sensor data. Hardware-in-the-loop uses the physical autopilot hardware connected to a simulator, as opposed to simulating the autopilot in software, too.

- I2C: Inter-Integrated Circuit. A serial bus that allows multiple low speed peripherals, such as sensors, to be connected to a microprocessor. See this for more.

- IDE: An integrated Integrated development Development Environment, such as the Arduino editor/downloader/serial monitor software. Often includes a debugger.

- IMU: An inertial Inertial measurement Measurement Unit. Usually has at least three accelerometers (measuring the gravity vector in the x, ,y and z dimensions) and two gyros (measuring rotation around the tilt and pitch axis). Neither are sufficient by themselves, since accelerometers are thrown off by movement (ie, they are "“noisy"” over short periods of time), while gyros drift over time. The data from both types of sensors must be combined in software to determine true aircraft attitude and movement. One technique for doing this is the Kalman filter (see below).

- Inner loop/Outer loop: Usually used to refer to the stabilization and navigation functions of an autopilot. The stabilization function must run in real-time and as often as 100 times a second ("inner loop”), while the navigation function can run as infrequently as once per second and can tolerate delays and interruptions ("outer loop”).

- INS: Inertial Navigation System. A way to calculate position based on an initial GPS reading followed by readings from motion and speed sensors. Useful when GPS is not available or has temporarily lost its signal.

- ICSP: In Circuit Serial Progammer. A way to load code to a microprocessormicrocontoller. Usually seen as a six-pin (two rows of three) connector on a PCB. To use this, you need a programmer, such as this one, that uses the SPI (Serial Peripheral Interface) standard.

- Kalman Filter: A relatively complicated algorithm that, in our applications, is primarily used to combine accelerometer and gyro data to provide an accurate description of aircraft attitude and movement in real time. See this for more.

- LOS: Line of Sight. Refers to a FAA requirement that UAVs stay within a pilot's direct visual control if they are flying under the recreational exemption to COA approval.

- LiPo: Lithium Polymer battery, aka LiPoly. Varients include Lithium Ion (Li-Ion) battery. This battery chemistry offers more power and lighter weight than NiMh and NiCad batteries.

- MAV: Micro Air Vehicle. A small UAV. More here.

- MAVLink: The Micro Air Vehicle communications Link protocol used by the ArduCopter and ArduPlane line of autopilots. See this for more info on MAVLink.

- Microprocessor: A microprocessor incorporates the functions of a computer's central processing unit (CPU) on a single integrated circuit or at most, a few integrated circuits (system clock, memory, peripheral device drivers).

- Microcontroller: A microcontroller (sometimes abbreviated µC, uC or MCU) is a small computer on a single integrated circuit containing a processor core, memory, and programmable input/output peripherals. Program memory in the form flash or EEPROM is included on the chip, as well as a typically small amount of RAM. Microcontrollers are designed for embedded applications, in contrast to the microprocessors used in personal computers or other general purpose applications.

- NMEA: National Marine Electronics Association standard for GPS information. When we refer to "NMEA sentences", we're talking about ASCII strings from a GPS module that look like this:

- $GPGGA,123519,4807.038,N,01131.000,E,1,08,0.9,545.4,M,46.9,M,,*47

- OSD: On-screen Screen Display. A way to integrate data (often telemetry information) into the real-time video stream the aircraft is sending to the ground.

- PCB: Printed Circuit Board. In our use, a specialized board designed and "fabricated" for a dedicated purpose, as opposed to a breadboard or prototype board, which can be used and resused re-used for many projects.

- PCM: Pulse Coded Modulation. A method used to digitally represent sampled analog signals. It is the standard form of digital audio in computers, Compact Discs, digital telephony and other digital audio applications. In a PCM stream, the amplitude of the analog signal is sampled regularly at uniform intervals, and each sample is quantized to the nearest value within a range of digital steps. Primarily useful for optical communications systems, where there tends to be little or no multipath interference

- PIC: Pilot In Command. Refers to a FAA requirement that UAVs stay under a pilot's direct control if they are flying under the recreational exemption to COA approval. See Line of Sight above.

- PID: Proportional/Integral/Deriviative control method. A machine control algorithm that allows for more accurate sensor-motion control loops and less over-control. See this for more.

- Pixhawk: The next-gen 32-bit autopilot, which succeeded APM. A collaboration between 3D Robotics and the PX4 team at ETH, the technical university in Zurich

- POI: Point of Of Interest, also known as Region of Interest. Designates a spot that a UAV should keep a camera pointed towards.

- PPM: Pulse Position Modulation. Signal modulation in which a set number of message bits are encoded by transmitting a single pulse in one of possible 2(number if message bits) time-shifts.

- PWM: Pulse Width Modulation. The square-wave signals used in RC control to drive servos and speed controllers.

- ROI: Region of Interest. Also known as Point of Interest (see above)

- RTL: Return To Launch. Return the aircraft to the "home" position where it took off.

- Shield: a specialized board that fits on top of an Arduino to add a specific function, such as wireless data or GPS

- SiRF III: The SiRF is a technology company that has developed a standard used by most modern GPS modules. Includes SiRF III binary mode, which is an alternative to the ASCII-based NMEA standard described above.

- Sketch: The program files, drivers and other code generated by the Arduinio IDE for a single project.

- SVN: Short for the Subversion Version-control Number repository used by the DIY Drones (in the past) and other teams for source code.

- Thermopile: An infrared detector. Often used in pairs in UAVs to measure tilt and pitch by looking at differences in the infrared signature of the horizon fore and aft and on both sides. This is based on the fact that there is always an infrared gradient between earth and sky, and that you can keep a plane flying level by ensuring that the readings are the same from both sensors in each pair, each looking in opposite directions.

- UAV: Unmanned Aerial Vehicle. In the military, these are increasingly called Unmanned Aerial Systems (UAS), to reflect that the aircraft is just part of a complex system in the air and on the ground. Ground-based autonomous robots are called Unmanned Ground Vehicles (UGVs) and robot submersibles are called Autonomous Underwater Vehicles (AUVs). Robot boats are called Unmanned Surface Vehicles (USVs).

- WAAS: Wide Area Augmentation System. A system of satellites and ground stations that provide GPS signal corrections, giving up to five times better position accuracy than uncorrected GPS. See this for more.

- ZigBee (related: Xbee): A wireless communications standard, which has longer range than bluetooth but lower power consumption than WiFi.

- The Arduino roadmap includes new boards with speciality functions, including GPS, ethernet, ZigBee wireless, and cellular wireless.

- The next generation of Arduino core boards will include Atmel's AtMega line with 64 I/O pins and 256k of memory.

- After that, the project will move to Atmel's 32-bit line of chips.

- People are considering implementing a proper debugger on the current Arduino platform, which would be great

- Arduino could be ported to the ARM chips pretty easily, although there are no plans to do so at the moment

- The project pays its bills by charging a license fee for officially certified third-party Arduino boards, such as the Arduino Nano

- People think Arduino was named after a 15th century Italian king. It's actually named after the pub where the founders first started planning the project.

- Projects such as our own ArduPilot and BlimpDuino, which use derivatives of the Arduino name, are generally fine, but should be sold as "Arduino compatible" rather than called Arduino boards.

- Massimo and I talked a lot about what the breakout product would be for open source hardware in general and the Arduino project specifically. Odds are that it's no one product, but instead speciality products in different industrial verticals. But we agreed the most fertile ground for open source hardware is in the emerging GPS+wireless space: location-aware, net-connected sensing devices, or what Bruce Sterling calls "spimes" (a neologism combining "space" and "time").

- Finally, he left me with a gift: one of the last remaining blank boards from the first version of Arduino, back in 2005. Only a few hundred were made. Here's a picture:

What do you think? Is this for real?