Want to Make an Antenna Tracker?

I am making this blog more for my future self than anyone else. That said, I think a lot of people will appreciate the contents as they too might have found that an antenna tracker (AT) build is not easy to find, nor are the explanations as to why they are built the way they are. I AM NOT AN EXPERT but I plan to show you how I pulled it off and therefore establish a "baseline" for anyone building their own antenna tracker. If you are ever confused as to which "whatever" I am referring to below, default your brain to aircraft and, good luck!

There is a lot to say here, so bear with me as I go over the basics.

What is an Antenna Tracker (AT)?

An AT is system that tracks where in the sky your plane/copter/whatever is. There are multiple methods for an AT to do this with. One is to use RADAR to find your plane (or copter or whatever) and feed the altitude/angles to the AT, this is way expensive and beyond the DIY needs. Another way is to have your plane emit a signal (or two) and a receiver on your AT electronically compares what it receives and uses that information to point the antennas with. This works as one emitted signal is slightly weaker than the other. There is an off the shelf system within DIY budget but if you use that system then it is usually not compatible with other "bells and whistles" you might want to put on your own AT.

The way the APM Mission Planner does it (that's the GCS software DIYdrones hosts, among others) is far more simple and yet very much as effective as the other two methods. Since your GPS on the APM board is already tracking where your plane is, it simply takes this data and shoves it to your AT and voila! instant tracking as good as your GPS can track it! My build uses the APM Mission Planner (MP) in conjunction with the APM2.

Why should I build one?

Easy. Two things, first it allows you to use a category of antennas broadly referred to as directional antennas. There is the Yagi and the Patch style as the most commonly used. These suckers increase your range by concentrating both the power that carriers your commands from the AT to your aircraft AND by increasing the sensitivity to the signals your aircraft is putting out. The tradeoff is that behind the directional antenna you get basically nothing very useful. That directional antenna must be pointing (within a certain amount of error) at your aircraft, otherwise you will loose link.

The second reason is the cool factor. You can add about 30 points out of 100 to the cool factor score of your drone build. No kidding!

Enough Talk, Gimme the Skinny!

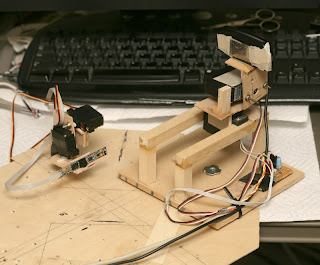

Ok, this is the AT build component explanations, then pics and instructions on how I built mine.

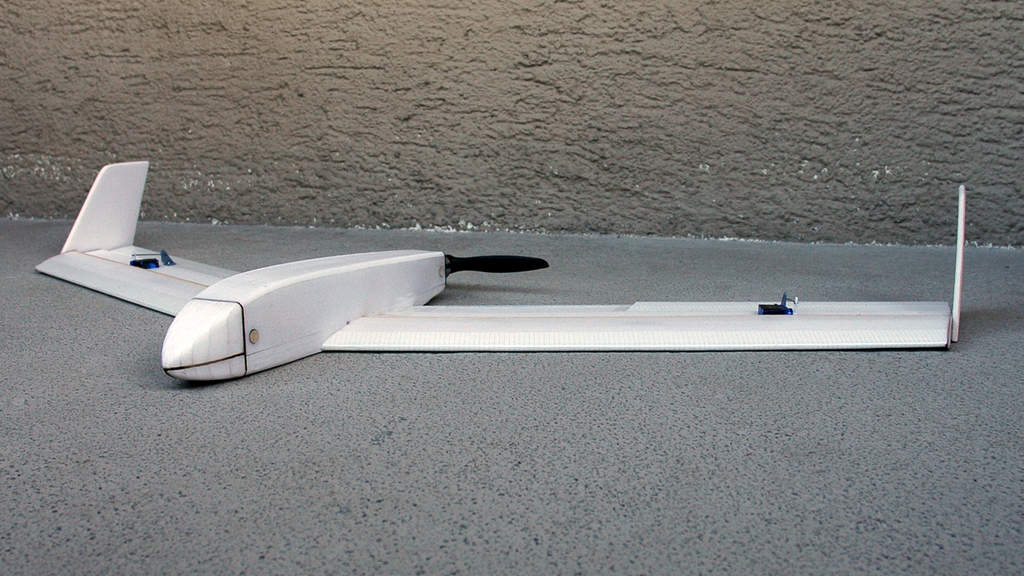

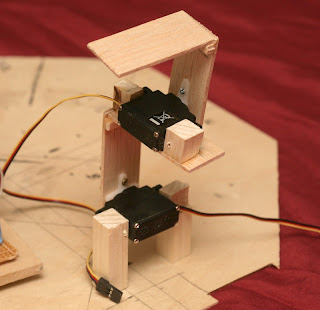

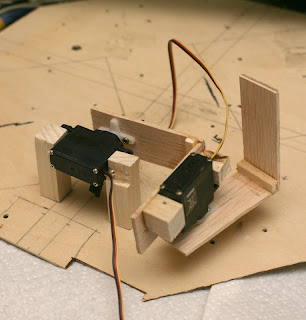

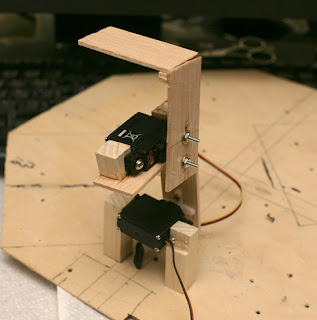

1) You will need a body that can support the tremendous weight of your antennas. 4 lbs is a "tremendous" amount of weight to throw around depending on what torque your servos can put out. This is the one I chose to use. It currently is holding two patch antennas each weighing about 12oz. You can design your own, but you'd best have a CNC solution as any inaccuracies could make it not track correctly and there goes your aircraft. All wood construction is fine for two antennas.

2) You need to decide which antennas you are going to use. Frequency is HUGE on this. Some antennas claim usability in a range of frequencies but that is NOT always legit. 915Mhz (aka 900Mhz) is very specific and your antenna could be "tuned" by the factory to "best" receive at 912Mhz and your screwed. Read READ READ the description on the antenna your looking at. I choose 1280Mhz (aka 1.2 or 1.3 Ghz) and 915Mhz patch antennas from L-COM. If you use the 3DR radios from the DIY store (as I do) you might be thinking "what about frequency hopping"? Your a nerd, but at least your an observant nerd. Your radio MIGHT try to go outside the "effective" bandwidth (frequency spread your antenna can use well) but if it does it notes the signal drop (aka RSSI, Recieved Signal Strength Indicator) and will compensate for it. Don't worry about this, just make sure your antenna is within the correct frequency range you will be using.

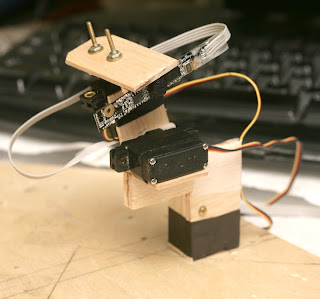

3) You will need two servos. One for the tilting action and one for the pan action. Tilt is the moving of the antennas only and the pan moves the whole AT, antennas and all. Servos are actually complicated little devices. I'll try to be precise as you can use the internet to find more details if you wish. You want a servo that can do at least 110 oz-in of torque for two patch antennas, I'd recommend at least the karbonite materials to ensure it never strips out, but you can get by on the nylon standby versions. Get a servo that does 90deg of rotation TOTAL. Different manufacturers explain the total amount of rotation a servo can do in different ways, do your homework. 90deg rotation total is a standard servo.

For the pan I'd recommend at least 200+ oz-in of torque for two antennas and karbonite or better, as in all metal gears. The reason for this beefiness is that when your panning range is at the limit of travel your AT will rapidly spin itself about 360deg in order to keep the antennas on target (1:50 second mark as an example). The faster it does this the less time you are out of communication with your aircraft. You can not avoid this behavior if you use APM Mission Planner as it is embedded in the software. Building an AT that does not care about the pan range is very expensive to do as it starts to involve what are known as slip rings. The military uses them and they are very nice, but very expensive due to the quality of slip ring involved. For this pan action you want at least a servo that can do 360deg of rotation. You really don't need more than that.

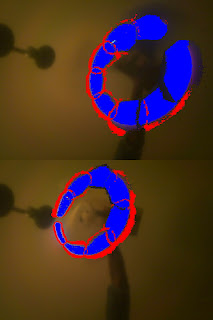

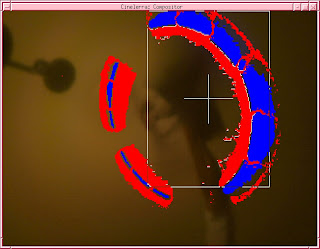

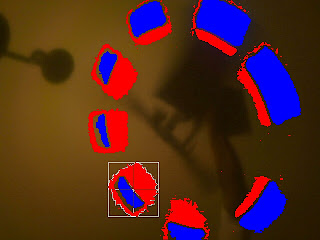

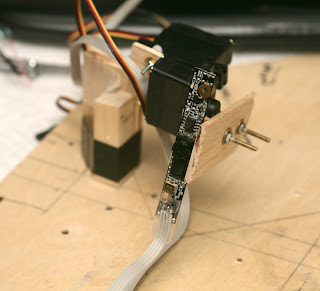

4) You will need something to take the information from your computer (again I used the APM Mission Planner to drive my AT) and turn those into a signal (numbers really) that your servo can use. APM MP has two options currently, one for Maestro and one for ArduTracker. The Maestro link is to a SERVO CONTROLLER card. It can run up to 6 servos with the input provided by the micro USB cable but you will only use 2 of them plus the power pins. The ArduTracker version uses one of the early versions of the APM called ArduPilot. It is stripped down and cheap, you might have one from years ago, I don't know much about it, but this is a build that HappyKilmore wrote up on both of them. I used it a lot and you can't go wrong reading it yourself either! No matter which controller type you use to drive your servos you WILL need to download and install the firmware for them. Maestro came preloaded and it looks like you need to find the firmware for the ArduPilot card from their website or this website's software library. Programming your servo controller is vital, use this as a guide. Basically you will find two numbers that bookend the total rotation your servo will do, then you will find the center of those bookends and then you will tell Maestro the "8-bit" range that it should use as commands to send the servo. It's way critical to get these right, I lost hair doing it.

5) Battery. Ok, servos run off of 5, 6 or sometimes 7V or more. Most of them default to the RC standby voltage of 5V. Mine are running off of 6V. My battery puts out 12V. If you do not find a way to step down the voltage from your battery to the CORRECT usable voltage for your servo you will fry your servo. Your servo motor might smoke or the little tiny tiny circuit board in it might smoke, either way the reliability of it is gone and you should get a NEW SERVO. If you don't and it fails in flight, you could lose connection! A BEC (Battery Eliminating Circuit) is what you are looking for here. I used this one. If you do your homework, you can look up the idle and full load current consumption of your chosen servos and pick a BEC that will handle that load. If you fail to get a BEC that can handle the spontaneous most highest ever load your servo could possibly generate then it will fry and your power to turn your AT will be gone, bye bye aircraft.

6) Battery Low Voltage Warning device. You don't have to use this, but I would. It's cheap and could save not only your battery but it will tell you when your AT is about to quit. Its as loud as a smoke detector going off! Buy a few of these and use them, don't be cheap like that.

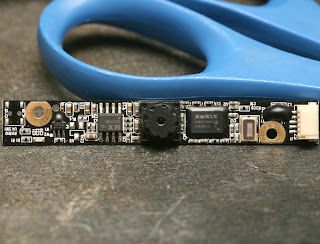

7) Video Rx and Tx. Rx and Tx is shorthand for Receiver and Transmitter. I'm not here to tell you about these but to tell you that whichever system you use make sure it can fit to your AT. Your AT is going to get crowded and messy.

8) Tripod. You could come up with another thing to use, but that would be tantamount to reinventing the wheel. The higher your AT is the further it can spread its signal. Try to get one that does not have a lot of protrusions like mine has. They will eventually entangle your wires. Pay attention to which type of connector the tripod uses so you can design your AT to link to it. Get one that is sturdy as a nice bit of wind could knock it over and your aircraft goes link dead. Your AT should weigh around 7 lbs max, probably less depending on what you use.

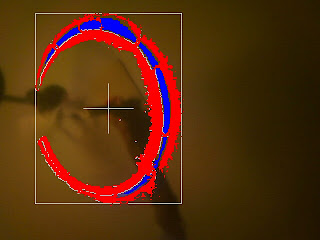

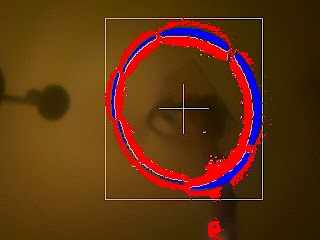

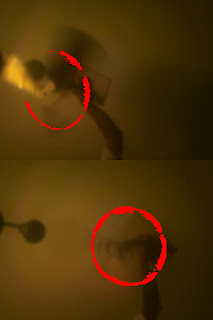

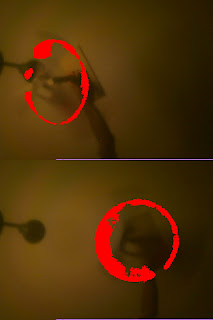

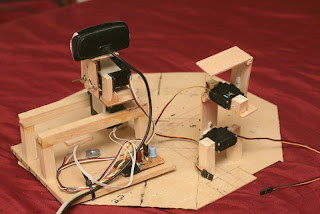

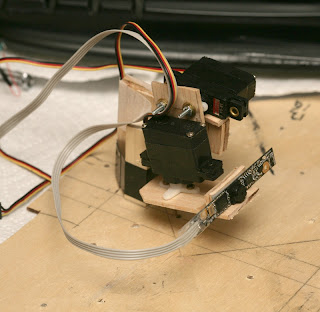

How Much Is a Picture Worth?

The Leg Bone is Connected to the Hip Bone...the Hip Bone is Connected to the...

Ok, here ya go:

*VELCRO AND ZIP-TIES you can use the crap out of them here!

1) Connect your servo controller board to your laptop, micro USB to USB for Maestro.

2) Servos connect to the servo controller board. For Maestro it will be servo 0 pin set for pan and servo 1 pin set for tilt.

3) Connect your battery to your BEC which is set at 5V or 6V or whatever your servos can handle (max it out). Connect the BEC to the servo controller board. For Maestro the pin set on the outermost is for the BATTERY power that will drive your servos (the USB cable powers the board). DON'T REVERSE THE POLARITY, buy new stuff if you did.

4) Connect your battery (assuming Li-Po here) to the Low Voltage detection device, pay attention to it.

5) Connect your antennas to your 3DR radio (NEVER TURN ON RADIOS WITHOUT ANTENNA ATTACHED, buy new stuff if you did). Connect antenna to the Video Rx.

6) You will need to splice off the power from the 12V side of the battery connection to feed 12V of power to your Video Rx, get some solder and a wet sponge, do a good job on the connection. Connect the power to your Video Rx.

7) Connect your 3DR 900Mhz radio to the laptop (after you have antenna connected).

8) Use a bunch of zip-ties to secure and bundle all the wires. This is important. If you do a bad job here your AT will bind while its tracking and down goes aircraft.

9) VELCRO AND ZIP-TIES FOR THE WIN!

I have included pictures from all angles of my AT (version 2). A few pointers here. Build your AT as light as you can. Get as beefy of servos as you can afford and fit. You can make a wireless version of this AT if you have telemetry radios like the 3DR or the Xbee kits the DIY store sells. I don't know how to do that but it is not going to be anymore complicated than what I have shown here, just more expensive. Testing is done in two ways, first you setup your AT outside and point it north before you fire it up. Then walk around the AT with your plane with everything linked up as if it was in flight. Another way is to load a previously recorded flight from the APM2 logs and watch your AT go at it as if it was there.

Test this thing out as best as you can, it's now a critical point of failure for your entire system. I don't recommend attaching your RC signal (typically your 2.4Ghz) radio. Keep that one unmodified so you have a backup that you can rely on.