Once upon an idea...

okay, okay, you all know the great idea about building a convertible tri - to planecopter. Oh yes Avatar like, old story no news. However, I started to work on one. I am still far away from anything that is convertible, but it might be soon a flying tri.

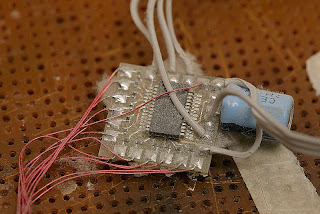

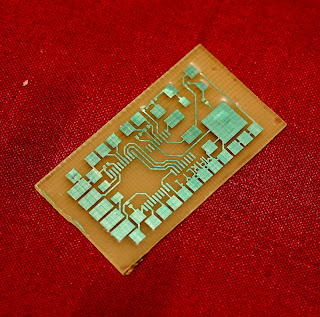

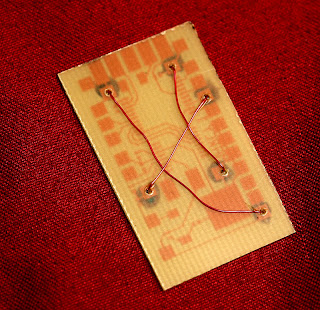

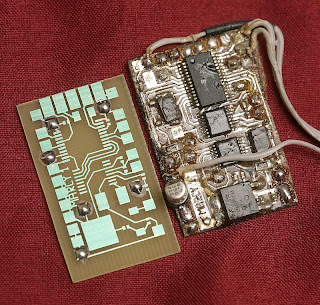

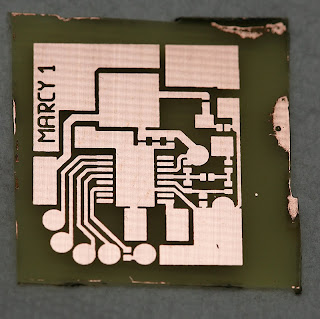

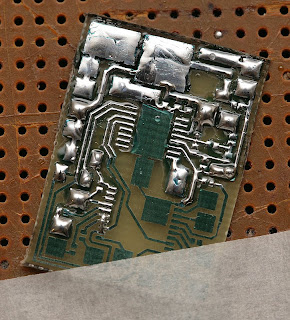

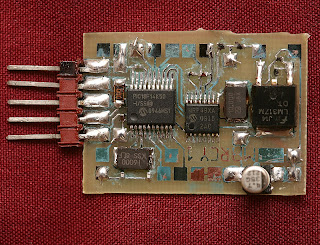

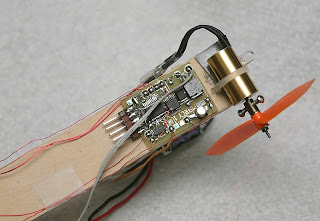

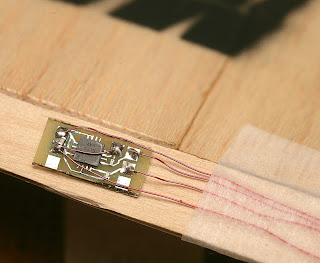

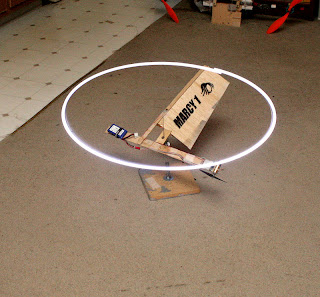

I'm using APM v1 with the 2560atmega the oilpan, gps, sonar EZxx. The frame is made out of CFRB, re-enforced with honeycomb. The arms, about 36cm each, are made from titanium, with a cold coated wolfram-aluminum coating. The three motors, 750kV; NTM 2836; about 250W each on 4S 2200mA LiPo. The props are 12"4.5; CCW/CCW/CW. I use a digital servo to rotate one of the motors, but I've already the setup to turn each motor 90° fwd/aft. All together, including a bunch of stainless steel A4 grade bolts and sel flocking nuts, the tri is on 1.7kg. Heavy beast. If I replace the titanium arms with carbon fibre, I could save about 150g. My body is more or less two round carbon sheets, 20cm diameter. Way to much material, but - who cares. I use as ESC the HK Blue Series 30A.

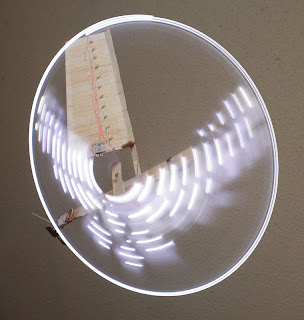

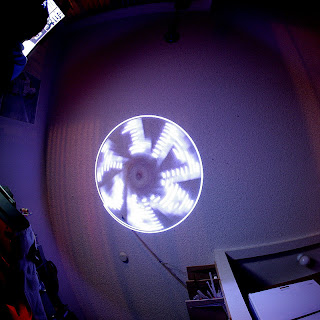

The pictures shows a partly disassembled tricopter. Troubleshooting...

The Firmware is now 2.2.6b. To reverse the yaw servo I had to change the fiftyHz loop in Arducopter.pde

APM_RC.OutputCh(CH_TRI_YAW, ( (-1 * (g.rc_4.radio_out - g.rc_4.radio_trim) ) + g.rc_4.radio_trim ) );

Time for takeoff...soon. I've to find the best CoG - but I'm not completely sure on how exact the CoG must be - clearly, as good as possible,...but maybe a few mm off? Fine too? Who knows.

I had some troubles, most are solved:

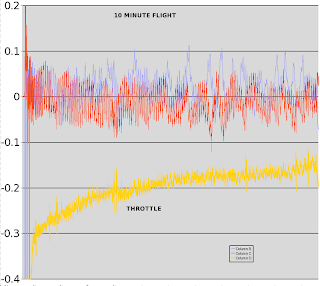

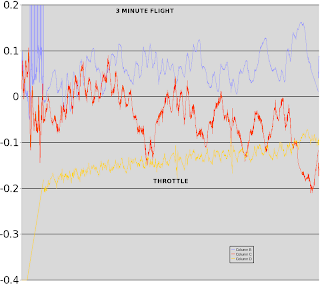

*) Vibration due to loose turn table mechanic. Some preload on the bearings and the problems was solved

*) Vibrations caused by unbalanced blades. The CW blade (from Arducopter Store) had a nice inbalance. Trimming was necessary

*) Yaw servo reversed in auto trim. Solved it with entering the update line, see above.

*) Took me a few minutes to figure out on how to load AC through Arduino. But finally easy.

*) Then was the little software updates when suddenly the YAW servo wasn't supported anymore (2.2b-2.2b5).

*) Too heavy, first I had two 2200Ah LiPoFe A123 6.6V in series. I've now one single LiPo 4S 2200Ah; reduced the weight about 150g.

*) Some flips because I connected the esc left/right reverse....STUPID I AM

*) Some flips because one ESC did not provide the same output power as the other one.....solved new ESC; I hope

*) Last but not least...working on the CoG.

I use a 6 Channel TX/RX Skytech Ts6i.

I hope I can lift of at about 60-70% throttle max. The next days will proof it. Then next step: full conversion. Mechanic is easy, but coding will take time.

Thanks for Igor and Don for support.