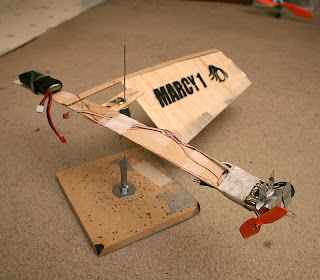

That there is the culmination of 30 months of off & on, hard work. The 1st stable hover of the Marcy 1 monocopter, under computer control. The last items were getting the takeoff as stable as possible, getting the altitude as stable as possible, aligning the azimuth as close to the camera angle as possible, & trying many PID values. Not only does it take off autonomously, but it can't be flown manually at all in this space.

There was a time when just a takeoff that stable was considered impossible, but we made it happen. Then there was a time when controlling the altitude of such a slowly spinning rotor was considered impossible, but we got it controlled. Finally, horizontal position was not considered controllable, but we managed to control it.

It's still a very unstable aircraft & this is the smallest space it could possibly fly in. The instability seems to be mainly from air turbulence building up from its own downwash, but there's just enough control with exactly the right calibration values to keep it in the air.

A descent was commanded near the end & the motor was killed, because 2 minutes is the point where it overheats. The video is from the machine vision camera.

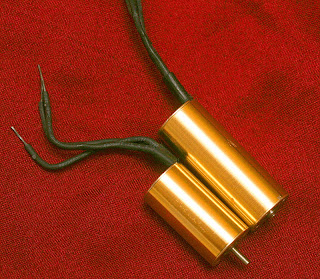

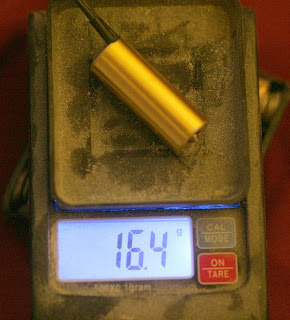

Always looking for punishment, we got another Feigao. This was 5250kV, 12 x 22mm. It may have been the same motor in the same store 3 years ago, but which we avoided because either the kV wasn't the highest or it was more expensive. Now, it was $32.50.

Feigao no longer sells motors directly. They're now sold as Electrifly Ammo & much lower kV ratings.

Ready to destroy some propellers.

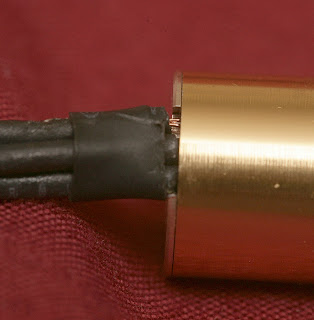

Then we discovered the wires were not inserted in the case for stress relief, but merely hanging off the magnet wire.

The previous one was 5400kV & slightly heavier.

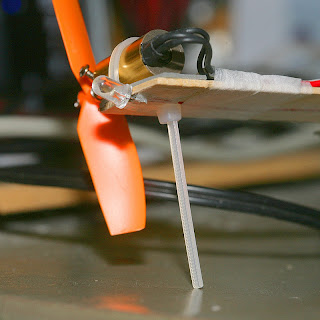

The 1st problem was the fact that the prop adapter only tightens when spinning counter clockwise. To act like a pusher, it needed to spin clockwise, loosening the nut. We have threadlock poured in a small reservoir on the nut. This has actually been holding.

Some ideas for balancing it have come to mind. Finding the center of wing pressure is the bigger challenge.

Zip tie landing gear is the new thing.

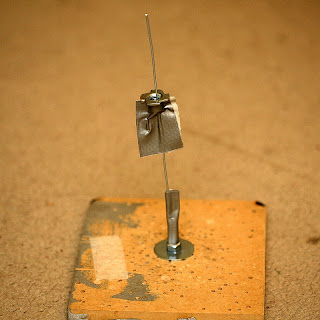

Attention turned to the spindle. Now we have flexing going all the way to the base. The closer it gets to lifting off, the more compliance the rod gives. Theoretically, it should be spinning closer to its COG than ever.

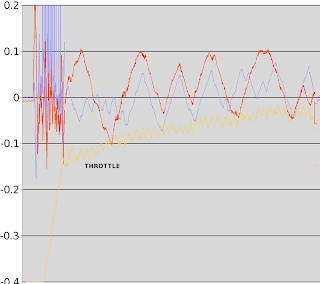

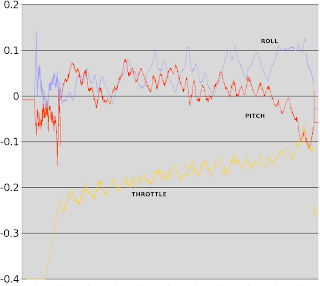

That gave a pretty straight takeoff, compared to before. Some gain tweeking got the altitude a lot more stable. There is still an undershoot right after takeoff, but after that, it's very stable. There was a time on the golf course, when we thought we would never get the takeoff profile tight enough to fit indoors.

Trying to control attitude in flight seems hopeless. After takeoff, there is too much variation in camera angle to get a useful orientation. Still pretty insane stability, compared to years ago.

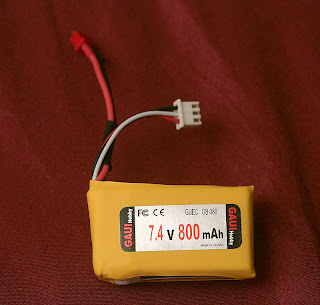

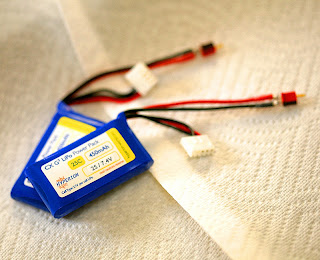

For the 1st time in 3 years, we got something we ordered from hobbyking, using the cheap shipping. It took 3 weeks. These ended up 7 grams heavier than our lightest 800mAh & slightly bigger than the old battery & we only have 2 Dean connectors.

A few sparks & a whiff of ozone later.

The Turnigies were 7 grams heavier, but the Gaui we had since 2009, before Gaui ever sold a quad copter, is 8 grams heavier than our lightest 800mAh.

The Turnigies came at 1/2 charge.

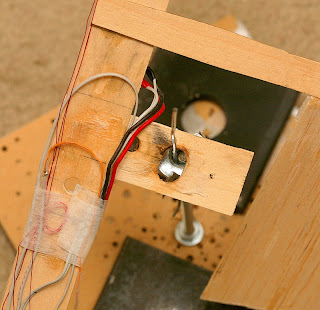

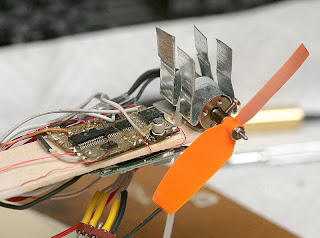

After proving hovering, Marcy 1 got a major overhaul.

It begins with a

The electronics are shifted to the end & a 3 gram heat sink is installed.

After all that weight shifting, it was more unstable than before.