10mm drill bit pushed into foam

Scapel cut along marked line

Poke out foam inside line

CA glue magnet in place

NOTE.. CA glue is fast drying so make sure you get your magnets the right way round before glueing otherwise you will be stuffed.

Assembly:

Open Bag #1 and take out 1 of the Main Frame boards. You'll also need 4 of the M3 x 25mm Male-Female Nylon Spacers and 4 of the M3 x 6mm Nylon screws that are in Bag #9. The main frame is supposed to

support both '+' and 'X' configurations. Take each of the spacers and put them over the hole closest to the

center of the three holes near the outside edge of the Main Frame board with the female side down. Secure each one with a screw from the bottom of the board. The spacers should NOT be installed over where the aluminum arms will be which depends on if you have a '+' or 'X' configuration. Now, take 4 - M3 x 20mm steel screws out of Bag #9 and place them through the innermost hole. These will end up going through your aluminum arms, so place them accordingly. In anticipation of installing the Power Distribution Board and to make it easier for ourselves when we do, it is best to install the spacers right now. Open Bag #3 and take out the 4 - M3 x 12mm Male-Female Nylon spacers and the 4 - M3 Nylon Nuts. Place the spacers through the innermost holes with the female side up that are not being used by the steel screws. These spacers should line up with the longer spacers already installed. Secure them from the bottom side of the board with a nut.

Now, remove the second Main Frame board and line it up with the first one. These two boards will sandwich the aluminum arms. Take out the 8 - M3 x 20mm Nylon Screws and 8 - M3 Nylon Nuts from Bag #9. Two of the nylon screws will be on either side of an aluminum arm and the steel screw will pass through the arm. Place the nylon screws through both Main Frame boards in the outermost holes of where your arms will be. Place a nut just barely on the other end; we will tighten it later.

Now, choose the size of aluminum arm you want to use. If you look at it, you should an elongated hole on both ends. Find the side where the hole is furthest from the end of the arm. This is the side that should face up and the end that your motor will mount to. The motor mount parts are located in Bag #7 and #8. The upper part of the motor mount is the larger piece. Take a M3 x 25mm Steel screw and place a steel washer followed by a nylon washer on it. Push it through the lower motor mount, the aluminum arm, and the upper motor mount. Take your 16/19 mm spacing motor and line it up with the holes on the end of the upper motor mount and the steel screw you just put it. Tighten the steel screw and use the mounting screws that came with your motor for the remaining three holes. Find 2 - M3 x 25mm plastic screws and nuts and place them through the remaining holes of the motor mount. These should press the motor mount pieces tightly to the aluminum arm and brace both sides of the arm. Do this for all four of the arms.

Slide each aluminum arm between the nylon screws of the Main Frame boards and pass the steel screw through them. Secure the steel screws on the bottom with the 4 - M3 x 10mm Female-Female Nylon Spacers found in Bag #4 and tighten the nylon screws so that the Main Frame boards are snug with the aluminum arms.

Take out the Battery Mounting Plate and the 4 - M3 x 6mm Nylon Screws from Bag #4 along with the velcro battery strap from Bag #9. Thread the velcro strap through the batter mounting plate ensuring that you have the correct side of the strap so that it will stick to itself. Make sure the recessed screw holes are also on that side.

Line the screw holes up with the nylon spacers on the bottom of the Main Frame board taking note of which direction you'll want the battery to be. In my 'X' configuration, I want the length of the battery to be facing straight forward and aft. Secure it with the 4 nylon screws.

Now, look at the Power Distribution PCB found in Bag #3. I didn't bother with using the PCB to route the signal cables of the ESCs because my cables are long enough to reach the APM directly. Notice there are 3 distinct trace areas on the PCB. The largest one in the middle is the positive and the two others are negative. Since the negative areas are not connected, we will bridge them together in two places with the 18 AWG cable included in Bag #3. Pass those through the bottom side of the PCB. The positive and negative cables from each ESC and from the battery need to be soldered on. Also place an additional solder layer of about 0.8 mm thickness on the traces. In my case, since this is a prototype, I want to be able to easily swap out parts like motors and ESCs. So, instead of soldering my ESCs directly to the PCB, I have EC3 connectors soldered on and I am not mounting the cabling inside of the arms.

Place the PCB into the 12mm nylon spacers and secure it with 4 - M3 x 6mm Nylon Screws from Bag #3.

Now, take out a carrier board from Bag #1. I used some nylon screws from the extra parts bag to mount my ArduPilot Mega board. Normally, you should mount the board so that the edges are parallel with the side of the carrier board, but mine is mounted at a 45 degree angle. I'll explain later in my thoughts section. Keep in mind when attaching your board that the edge opposite the right-angle headers must be the front of the Arducopter.

Place the IMU shield on top of the APM.

Take the second carrier board and attach the magnetometer (if you have one) as well as the receiver from your transmitter. If you take a look at the magnetometer, there are two arrows labeled 'x' and 'y'. The coordinate frame for aircraft designates the x-axis out the nose and the y-axis out the right wing. So, in the Arducopter, the x-axis should be pointing to the front and the y-axis to the right.

A velcro sticker is supplied in Bag #9 for mounting the receiver, but you may not be able to use it. I later found out the velcro adds too much thickness to the point where the protective dome doesn't fit, so I have mine secured instead with zip ties.

Place the carrier board that has the APM and IMU on top of the 25 mm Nylon spacers already on your frame. Take the other 4 - M3 x 25mm Male-Female Nylon spacers out of Bag #9 and screw them on top of those. Place the second carrier board with your magnetometer and receiver on top of those spacers and secure with a M3 nylon nut.

All of the parts for the protective dome and landing gear are in bags #5 and #6. The upper and lower dome center have elongated slots in them that the protective dome arches slide into. Secure with 2 - M3 x 20mm

Plastic screws and two M3 plastic nuts. The top carrier plate will have more room if you hold the dome centers with the nuts being placed on top and the screw head on the bottom. Two extra nuts are included for both sides of the dome center, but I don't think they are necessary as the dome arches are supporting it.

If you look at the end of the arches, notice that there is material removed from one side of it between the 3 screw holes. This is the side that is against the aluminum arm.

The Landing Gear Fins also have material removed on one side and they attach with 3 - M3 x 20mm Plastic Screws and Nuts. Keep the nuts loose until all of the landing fins are on so that you can center the entire Protective Dome on the Arducopter. Once it is centered, tighten the nuts. (Some people may find it

easier to attach the Protective Dome Arches and Landing Fins to the aluminum arms and then snap the Dome Centers in place)

Thoughts:

When I initially received the box containing the ArduCopter Beta Frame via EMS Express from Jani, I was surprised how small it was. Upon opening it, everything was neatly packed. There was an 8 1/2" by 11" piece of paper with a parts list and letter on it along with individual bags containing parts and two sets of aluminum arms (21.5 cm or 28 cm) wrapped in padded foam. I set about putting it together even though there were no instructions available. It definitely helped that the bags were grouped together into ones such as 'Battery Mount'. That way, I at least knew which sizes of screws and spacers belonged to each component. Like my Power Distribution PCB video, I filmed myself putting it together; although it wasn't always correct or in the optimal order as I would discover later. I might post that video later.

I'm using 12 x 3.8 APC props and decided to go with the longer of the two sets of included arms at 28 cm. All of the holes were drilled precisely and I didn't have any problems with alignment. However, I had a fair number of quality problems with the plastic nuts. I don't know if it was because the threads were crooked or what, but quite a few of the nuts wouldn't go onto the screws farther than the initial bit. Flipping around the nut didn't help. Thankfully, Jani included a 'Beta Spares' packet that provided enough spares to cover the ones that didn't work.

One of the problems I had was with Bag #8. As you can see in the diagram below, the parts list didn't match the parts I received and the parts received weren't all the parts I needed to mount the motors. The innermost screw on each motor is a steel screw that goes through both motor mounts, the aluminum arm, and into the motor. Only one of these screws was included for the entire frame. None were included in the Beta Spares bag, so I went and bought some at a local hardware store. The motor mounts themselves are a fantastic design. I love not having to use the 'plus' motor mounts and the spot for an LED to slide into is a nice touch. I thought there was supposed to be a cover for the LEDs that keep them pressed in their slot. If there is, some longer plastic screws will be needed to pass through the extra thickness.

Another problem I had was with '+' versus 'X' configuration. It is supposed to allow for both, but I don't see how to mount the carrier boards for the 'X' configuration and maintain the same structural support and ease of mounting the APM+IMU. Ideally, an edge of the carrier boards faces the direction of flight so that there are no spacers in the way of mounting the APM+IMU and so there is nothing blocking the I/O ports of the APM. With the '+' configuration, it works, but with the 'X', you're either faced with mounting the point of the carrier board

facing the direction of flight like I've done on mine, or mount it the other way. The problem with the other way is that the Aluminum arms are there. I could increase the distance between the main carrier boards to allow a screw head to fit between the top carrier board and the aluminum arm, but then it doesn't benefit structurally

from having the main frame board being pressed against both sides of the aluminum arm. Another option would be to drill an extra hole all the way through the aluminum arm. With the corner facing my direction of flight, I have everything mounted, but it is not perfect and some of the I/O ports are blocked. Another thing is accessing the APM+IMU. It is difficult to access things like SW1 for data logging.

A velcro sticker was included for mounting the receiver (I have the one that comes with the Turnigy 9x) to the top carrier board, but the velcro added too much thickness so that the receiver couldn't fit underneath the dome center. I just used cable ties because they didn't add as much thickness although they are still pressing

against the dome center. The dome arches were a little hard to snap into the dome

centers. Maybe increasing the notch that faces upwards would provide a better lock. There really isn't a reason the top one has to be flush with the upper dome center. The bottom one is nice being flush so that it doesn't restrict mounting on the top carrier board. I would definitely like to see some longer landing fins and maybe an optional protective dome that protects all of the electronics instead of just protective arches. With my 4900 mAH battery, there is only about an inch of ground clearance for the battery. Combine that margin with a soft lawn and the small surface area of the landing fins, the fins slip into the ground and the battery may take a hit on the landing. So, I'd like to see options for longer landing fins and some to permit a camera to be mounted beneath the frame. I imaged the battery mount is perfect for about a 2200 mAH battery, but my 4900 mAH might be about the limit of what it can

mount.

Could traces be added on the bottom side of the Power Distribution PCB to connect the negative sides? That way, two of the wires wouldn't be needed to jumper them. My view of this frame is to be bundled together with the electronics, motors, etc, to make a complete kit and make it easy for people to know what to buy and put together. Every little bit of wire and soldering that can be avoided would make it easier for people. I didn't even solder the connectors for the signals of the ESCs because my cables are long enough to reach the APM. Is there a benefit to routing them to the PCB and then adding an extra cable to the APM? It just seems like more complications and wire to me. Also, could some holes be added for the (+) and (-) of the ESC to connect to instead of just mounting them flat across the top trace?

A foldable frame would make it easy for transportation. I think this was designed for it and I see how removing one of the nylon screws bracing an aluminum arm on the Main Frame would allow for the arm to pivot around the steel screw, but wouldn't the Protective Dome also have to be removed to make it fold? Maybe we can find a way that would make it a quick process, but still be structurally sound in flight.

I just mounted my ESCs on the outside of the arms since this is a prototype anyways. I have Turnigy Plush 30A and I would need an extension to be able to mount the ESC on the main frame and get the cables through the arms because the cables on the ESCs aren't long enough.

These thoughts were all intended as constructive criticism. I am impressed by the design, weight, and especially the motor mounts. Great job on the frame Jani! I'd like to continue working with you guys to improve ArduCopter!

The cool Robot Operating System from Willow Garage is now running on coax helis and quads. You can get it on the $5,000 Skybotix CoaX heli and drives are now available for high-end quads, too.

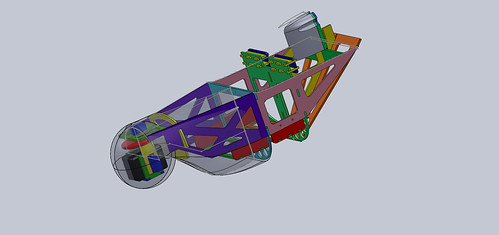

new design i am working on . built around sony FCB-EX11D 10x optical zoom block camera

this camera can be controlled through rs-232 com and has many cool features including built - in OSD

SPECS:

cruise speed - 27knots

max speed - 55knots

max weight - 4.4 lbs

flight time - 1 hour+

climb rate - 2000 ft/min

features :

EPP wings and tail

carbon fiber tail boom

clear lexan ,fully removable top hatches

clear acrylic "camera quality" dome

pan/tilt camera mount

retail price will be approx $150-$200

Here's a copy of our Deliverable 2 video that we presented for entry into the 2010 UAV Outback Challenge.

We are using a Penguin-B UAV airframe from UAVFactory(.com) its a very stable platform and as seen in the video it is flying at an AUW of 15kg (~30lb) and tootling along at 1/3rd throttle.

Thought some of you might find it interesting....enjoy.

Spotted at the DefCon hacker conference this year, the ArduPilot-powered WiFi Aerial Surveillance Platform (WASP), basically a UAV with WiFi sniffing capability. It flies until it finds an open WiFi access point and then loiters over it. Here's a video interview with the creators at the conference: