Senior Telemaster UAV Drone[Mechanical Part]

Participants: Jinwoo Baek, Rufus Cochran, Patrick Duncan & Matt Runchey

Parts:

- Ready Built Senior Telemaster, Yellow (OVERSIZE) / Product #: HLA007 / URL:

- SuperTigre SUPG0235, 11003544, G90 Ring w/ Muffler / ****

- Exacto Knife / Joe's Hobby Barn

- Gripper Pads / Menards

- Drill / Amazon.com

- Sharpie / Menards

- Hangar 9 / Heat Sealing Iron / Joe's Hobby Barn

- 1/16'' Drill bit

- Philip screwdriver

- #8-32 Stove Bolt, 2 1/2" Long x 5/32" Diameter Round Head, Qty. 6 / Menards

- Tool Shop High Speed Steel Drill Bit, 5/32" / Menards

- #8 Flat Washer Zinc / Menards

- #8 Lock Washer Bronze / Menards

- DU-BRO Cat. No. 158 / Steel Landing Gear Straps / Joe's Hobby Barn

- DU-BRO Cat. No. 690 / 32 oz. (950cc) Fuel Tank / Joe's Hobby Barn

- DU-BRO / Pushrod Connectors / Joe's Hobby Barn

- Master Airscrew / 15x6 in. K Series Propellers / Joe's Hobby Barn

- DU-BRO Cat. No. 257 / Heavy Duty Hinges / Joe's Hobby Barn

- Futaba S3004 standard size servos / Joe's Hobby Barn

- EXRA115 Expert Electronics/ Servo Extension 12" Standard / Joe's Hobby Barn

- SIGSH710 / Easy Hinges / Joe's Hobby Barn

- DU-BRO Cat. No. 125TW / 1-1/4" Dia. Tailwheel / Joe's Hobby Barn

- SIGSH709 / L.G. Retaining Straps with screws / Joe's Hobby Barn

- DU-BRO Cat. No. 257 / Heavy Duty Hinges / Joe's Hobby Barn

- DU-BRO Cat. No. 376 / Tailwheel Bracket / Joe's Hobby Barn

-

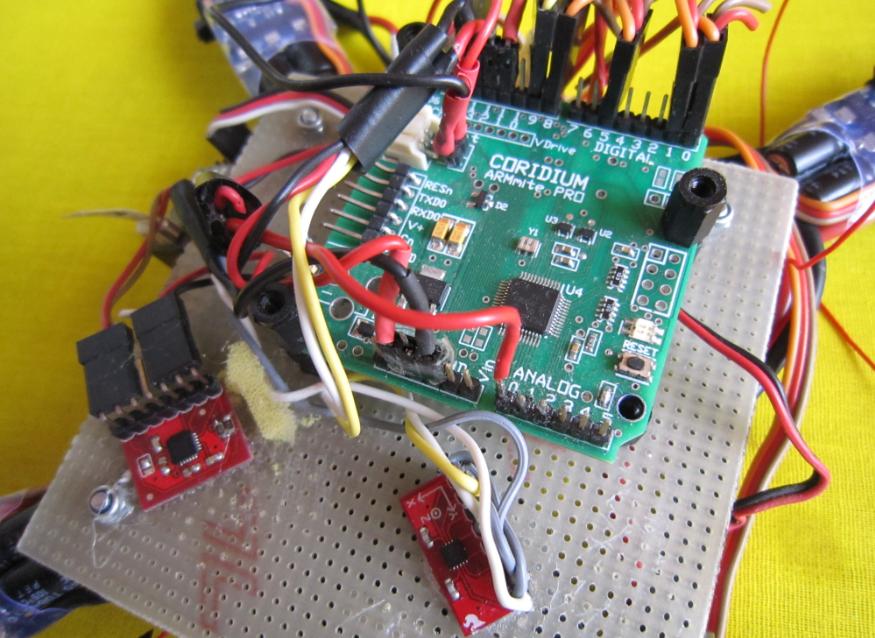

Building the Senior Telemaster ARF

Step 1: Landing Gear

Our team made changes with the strap material. We were concerned about the original strap material because during installation stress fractures were observed, which is illustrated on Figure 1. So, we substituted the plastic straps with the Gripper Pads found in Menards. The Gripper Pads, shown on Figure 2, material is more flexible, variable in size and easy to manipulate. Also, due to concerns of its strength, we increased the number of straps from 4 to 6 as shown on Figure 3.

Figure 1: Stress fracture on the original strap

Figure 2: Alternative material for strap

Figure 3: Display of changed straps

unchanged recommendations:

- 2.60mm Aluminum screw replaced with Metal Material screw

Step 2: Installing the Glow Plug Engine

We decided to use the SuperTigre G90 engine considering the heavy payload of camera system, communication system, and sensors, over the SuperTigre G60.

There were various concerns that were brought up in the process of installing the glow plug engine on the plane. According to the instruction manual of the engine, it requires us to keep the Fuel Pick-up line no lower than 3/8" from the high speed needle. This creates various issues in installing the engine. After searching the web and asking experts in building RC planes, our team concluded that the muffler's pressure fitting into the vent of the fuel tank would be enough pressure to overcome any fluid-dynamic discrepancies for a smooth supply of fuel to the engine. So, after drilling a set of four holes in thinking to mount it up-side down as shown on Figure 4, we finally came to install the engine on as shown on Figure 5. Both #8 lock and flat washers were used on the #8-32 stove bolt that was cut into size.

Figure 4: Failed attempt to mount the engine inverse

Figure 5: Final engine mount

Step 3: Installing the Tail